METAL ROLLING

PROCESSES

Metal Rolling

Shape Rolling

Ring Rolling

Thread Rolling

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Forging

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

Rotary Tube Piercing

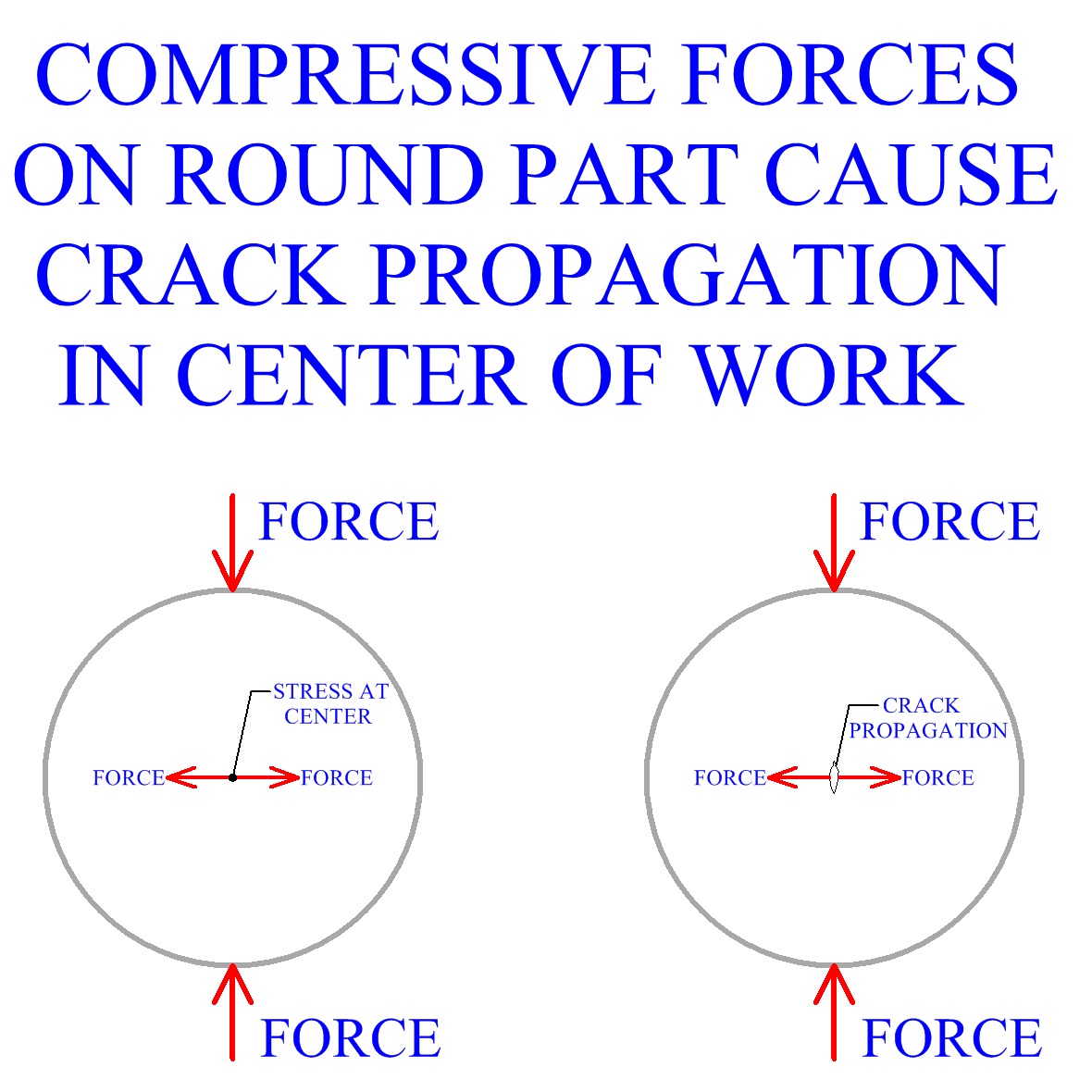

Rotary tube piercing, also called roll piercing, or the mannesmann process, is a hot forming process that can manufacture long lengths of seamless tube and pipe. Compressive forces applied to a cylinder will create internal stresses at the center. These stresses result in crack propagation.

Figure:152

|

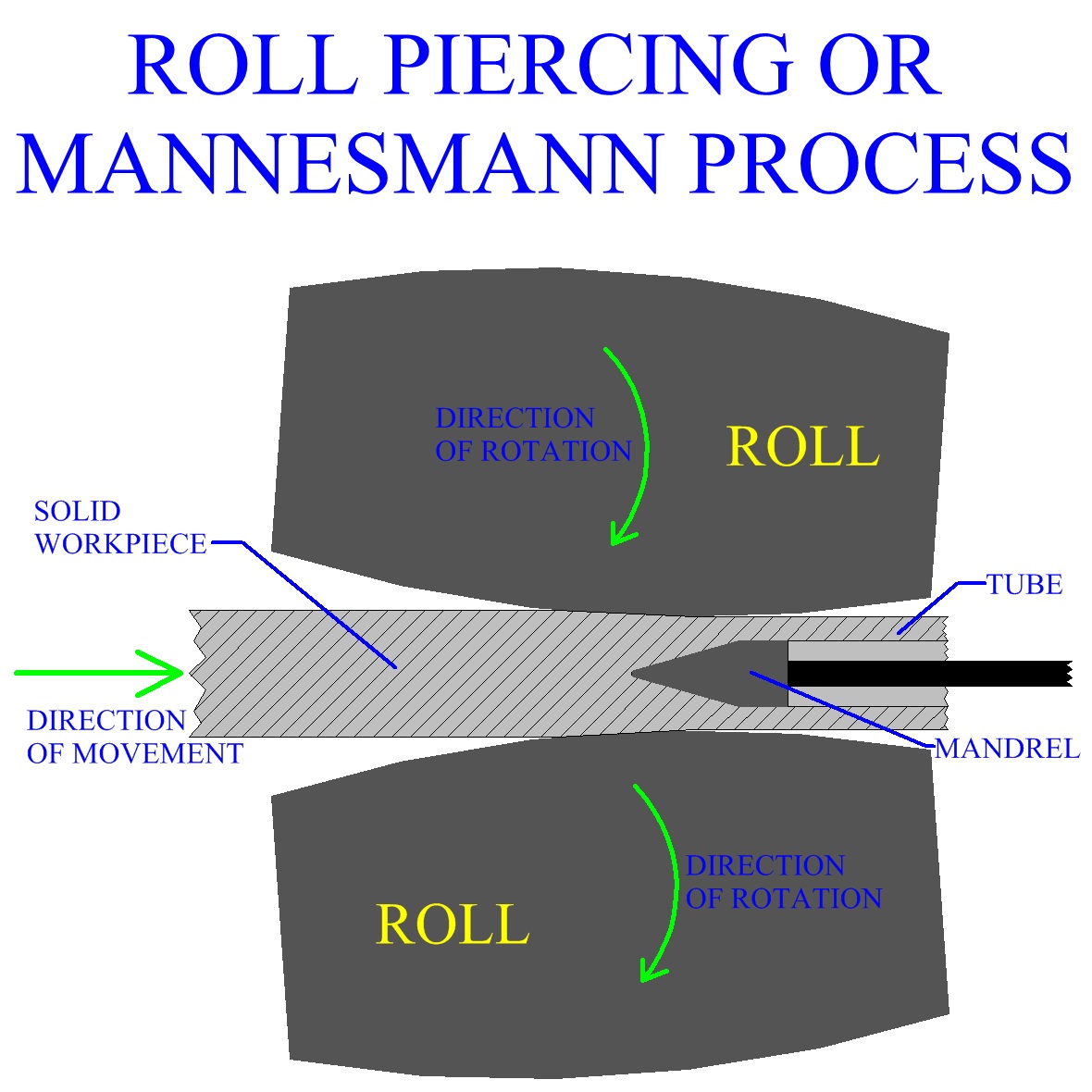

Rotary tube piercing manufacture relies on this physical principle. A round stock is center drilled at its end and compressive forces are applied by the use of two rolls. A mandrel is used to shape and size the internal cavity formed at the center of the round stock. The rolls rotate in the same direction and are oriented at an axis that is at a slightly skewed angle to the axis of the part. This causes the stock to be pulled through the rolls and forces it against the mandrel.

Figure:153

|