SHEET METAL FABRICATION Sheet Metal Manufacturing Sheet Metal Cutting Sheet Metal Bending Deep Drawing Sheet Metal Sheet Metal Spinning Rubberforming Sheet Metal High Energy Rate Forming Of Sheet Metal MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Powder Processes

Ironing Of Sheet Metal

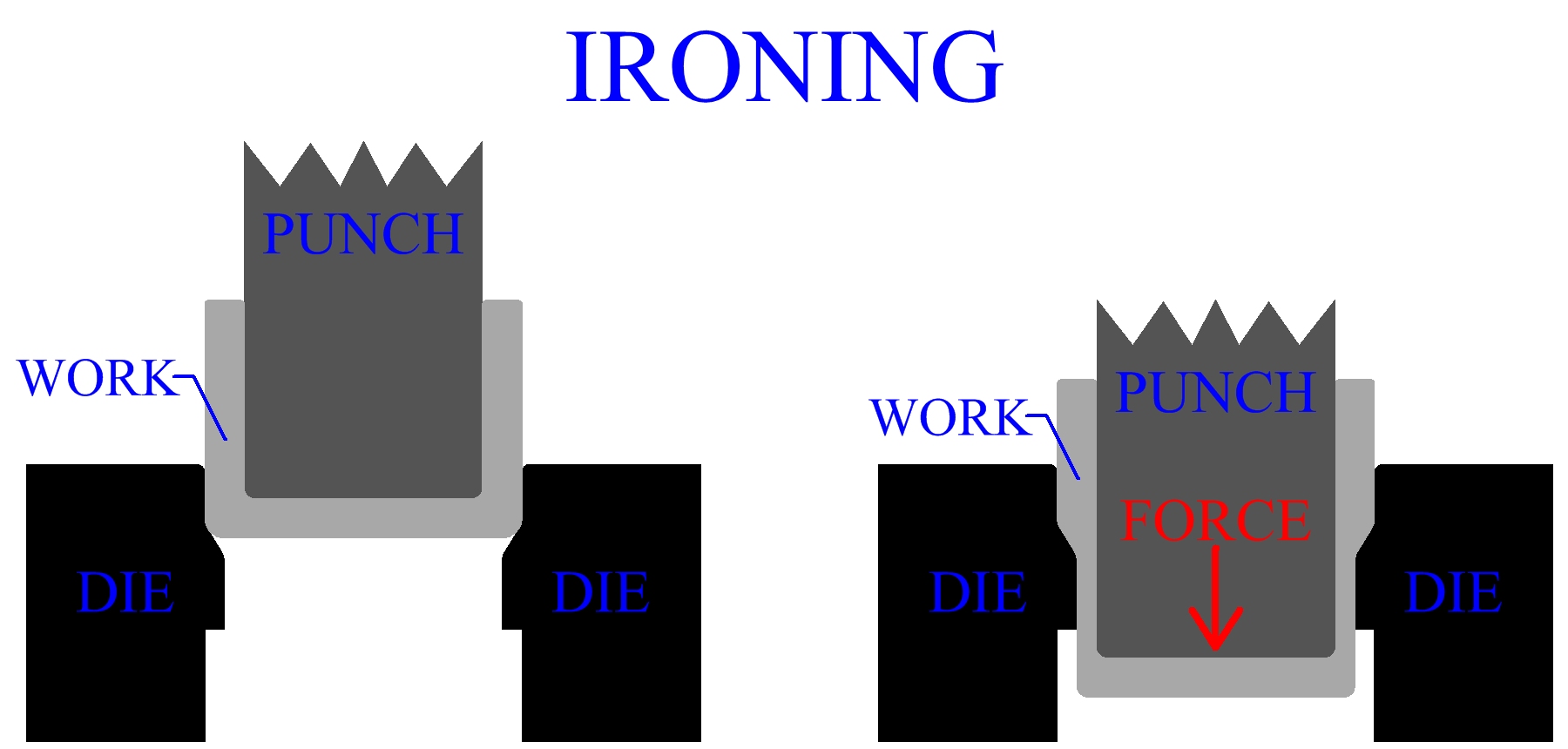

Ironing of sheet metal is a manufacturing process that is mostly used to achieve a uniform wall thickness in deep drawings. Variation in wall thickness often exists in parts produced by deep drawing, as discussed in the previous section. Ironing of sheet metal can be incorporated into a deep drawing process or can be performed separately. A punch and die pushes the part through a clearance that will act to reduce the entire wall thickness to a certain value. While reducing the entire wall thickness, ironing will cause the part to lengthen. The percentage reduction in thickness for an ironing operation is usually 40% to 60%. Percent reduction can be measured (ti - tf)/ti X 100%. With ti being initial thickness and tf being final thickness. Many products undergo two or more ironing operations. Beverage cans are a common product of sheet metal ironing operations.

Figure:310

|