| Manufacturing Home

SHEET METAL

FABRICATION

Sheet Metal Manufacturing

Sheet Metal Cutting

Sheet Metal Bending

Deep Drawing Sheet Metal

Sheet Metal Ironing

Rubberforming Sheet Metal

High Energy Rate

Forming Of Sheet Metal

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Rolling

Metal Forging

Metal Extrusion

Metal Drawing

Powder Processes

|

Metal Spinning

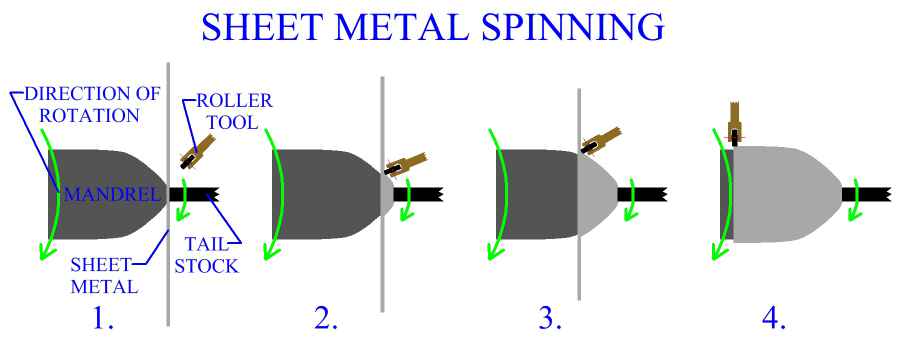

Metal spinning, also called conventional spinning or just spinning,

is the forming of an axis-symmetric part

over a rotating mandrel. Force is delivered by a tool with a rounded end or a roller.

A flat, or possibly preformed, work piece is held between a mandrel and tail stock.

As the apparatus rotates, the tool applies localized pressure to the work while it

gradually moves up the mandrel. This causes the sheet metal work to be wrapped

over the mandrel, thus taking its shape. Metal spinning is commonly performed cold, but

in some cases parts may be subject to warm or hot spinning. Spinning is capable of

producing large parts with diameters as high as 20 feet.

The tooling in a metal spinning operation is generally made from tool steel. The mandrel

in some cases may be made of wood. Containers with bottle or tapered necks

can be manufactured on collapsible mandrels, that are disassembled and removed from

the formed parts. Set up costs for metal spinning are usually low. Conducting a spinning

operation is relatively expensive on a per unit basis. Deep drawing is usually the main

alternative manufacturing method to metal spinning, for producing parts. In contrast, deep drawing

often requires a high initial investment for set up, while the cost of production per part

is low. For these reasons, deep drawing is more useful for mass production of

parts. Spinning is employed for small numbers of parts, unique, curved, or varied

parts and large parts. Operator skill is important in metal spinning. CNC machinery is now

replacing the operator in many cases. CNC spinning gives a high quality consistent

product.

|

PRIVACY POLICY

|