Manufacturing Home

FORGING

PROCESSES

Metal Forging

Drop Forging Hammers

Hydraulic And Mechanical Presses

Metal Piercing

Metal Sizing

Roll Forging

Swaging Or Radial Forging

Metal Hobbing

Metal Ball Forging

Orbital Forging

Ring Forging

Riveting

Metal Coining

Isothermal Forging

Trimming Of Forged Parts

High Energy Rate Forging

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Rolling

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

|

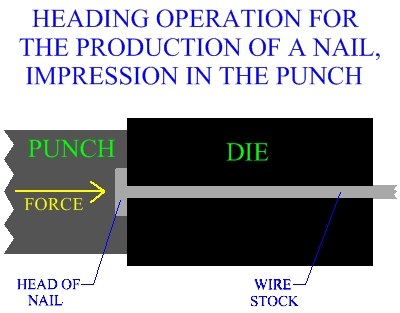

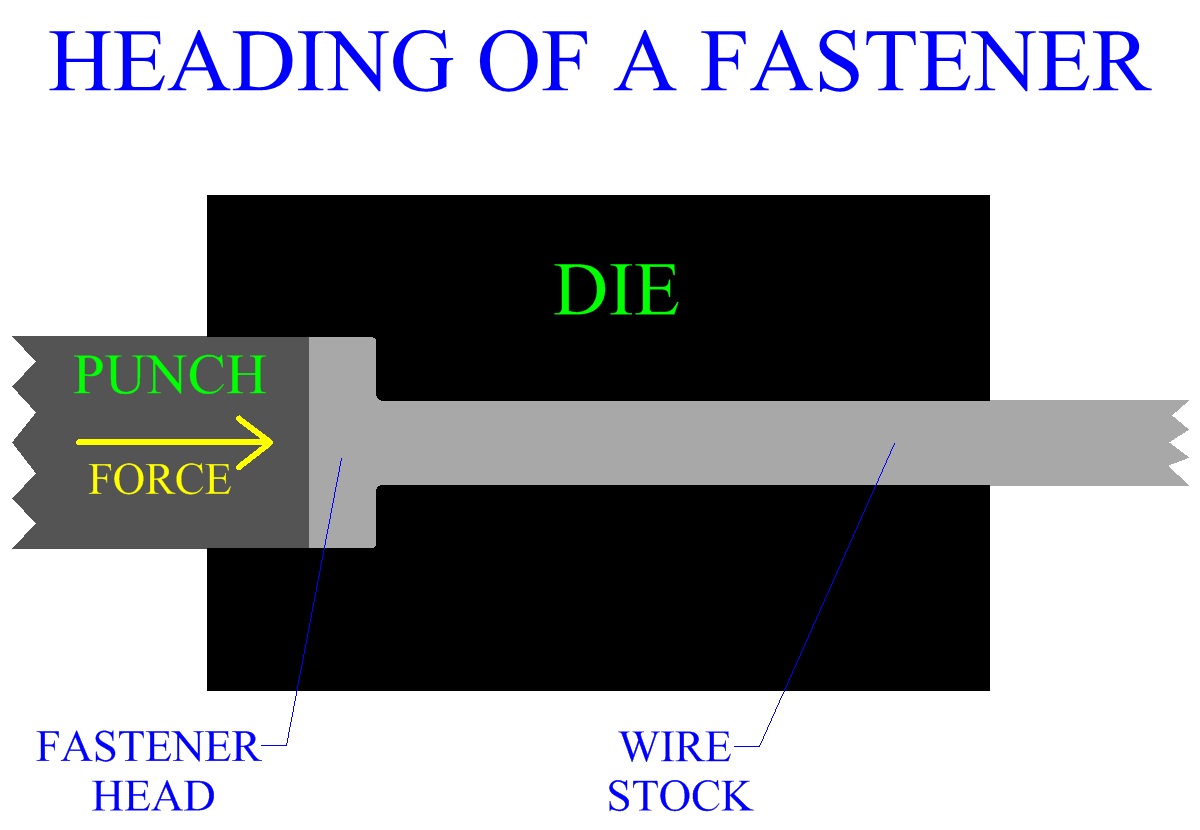

Heading Or Upset Forging

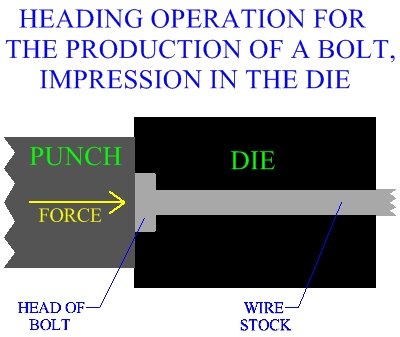

Heading or upset forging is a process by which stock, (typically cylindrical),

is upset at its end in order to increase the cross section of the material in this area.

This metal forging process may be hot, but is often a cold working operation.

Cold working will take advantage of the strengthening of the material in the region

worked. Unlike upsetting, as discussed under open die forging, upset forging can

employ closed die. For typical industrial applications, heading, is mostly performed

horizontally, as shown in the diagrams. Heading is a manufacturing process used

extensively in the production of fasteners that include nails, screws, nuts and bolts.

Due to the enormous quantity of fasteners produced in modern manufacturing industry,

heading is the most commonly used metal forging process in the world today. The

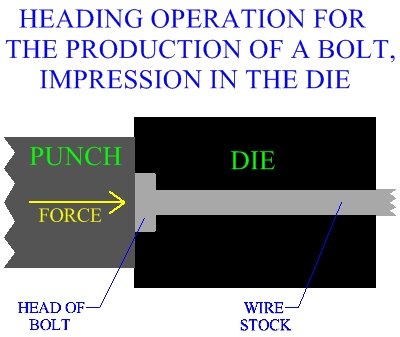

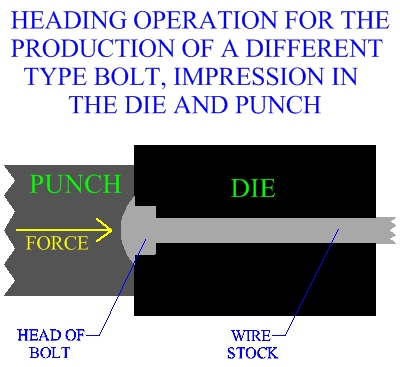

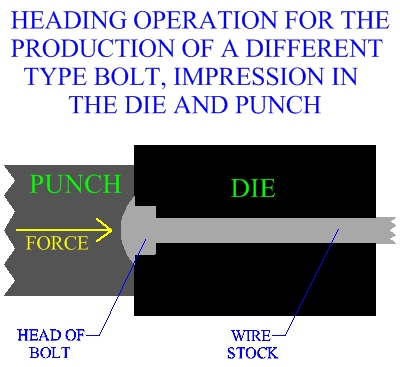

impression in the head may be forged in either the punch, the die, or both.

Figure:183

|

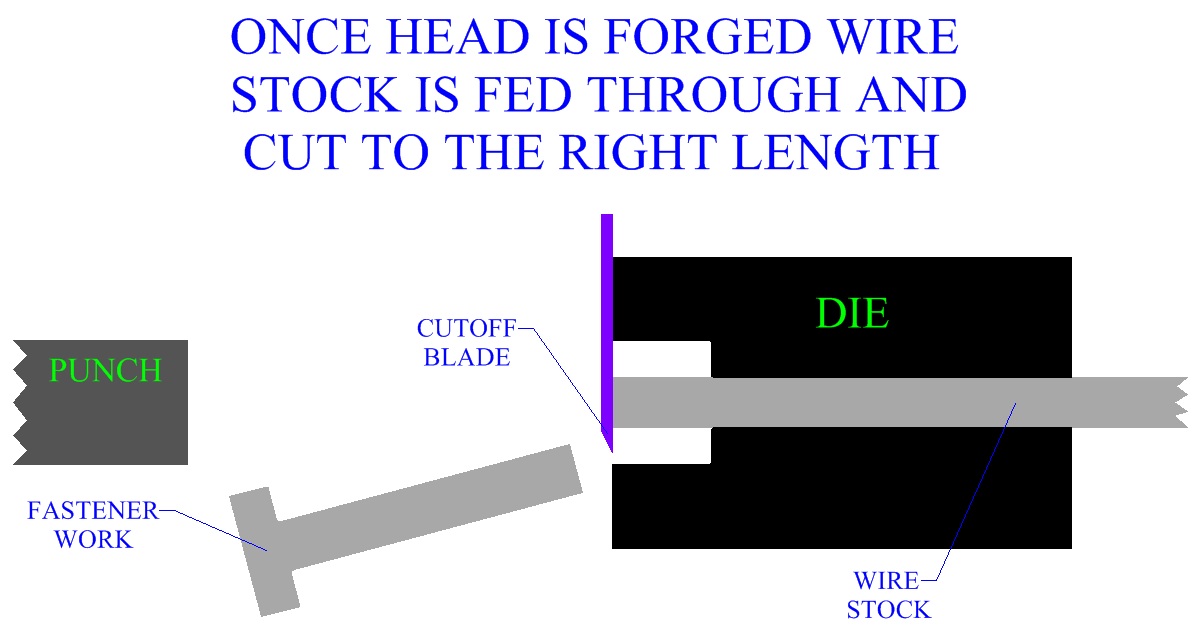

Figure:184

|

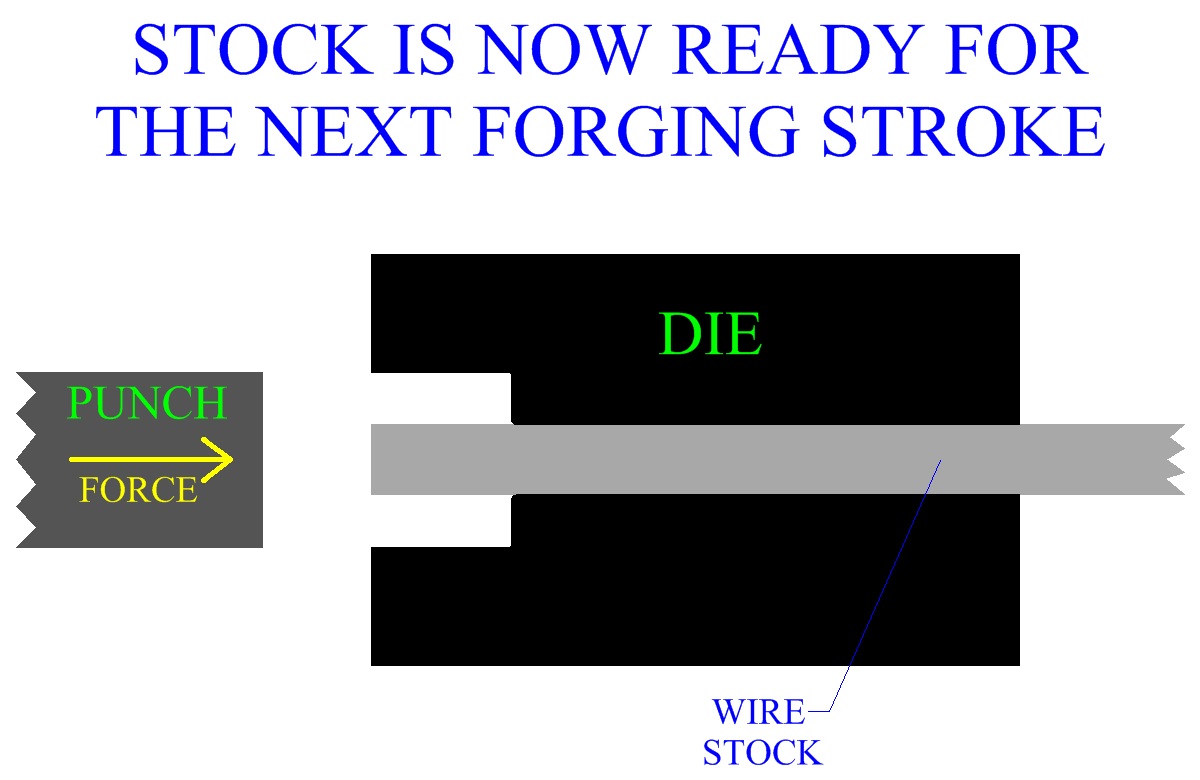

Figure:185

|

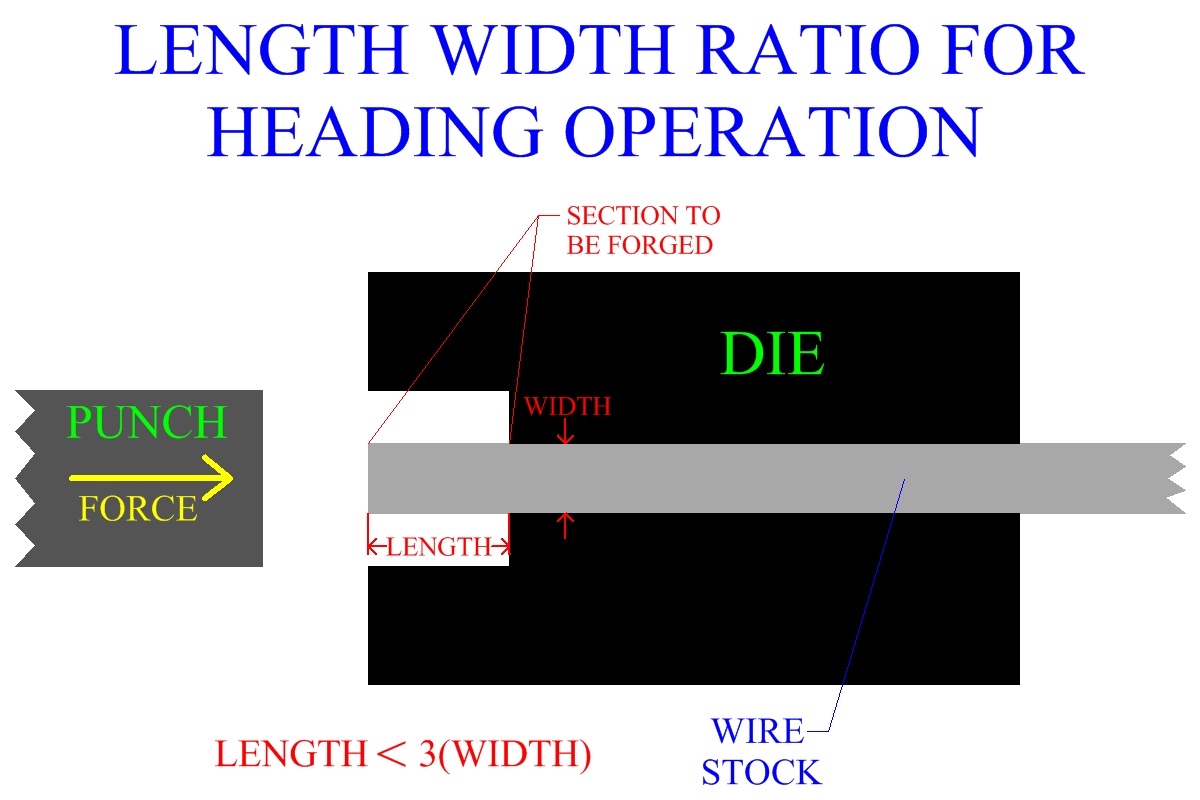

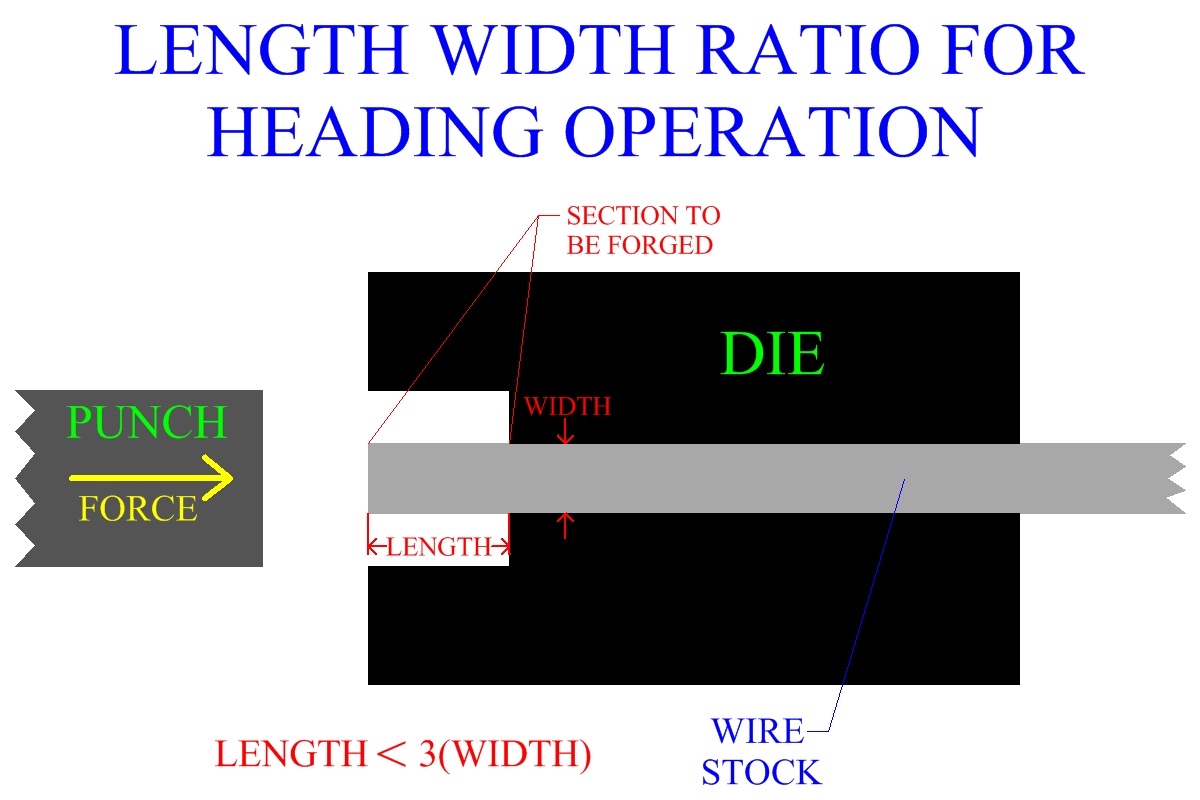

In order to ensure proper metal flow during the forging of the head, and thus

avoid bending or buckling of the stock material during compression, the length of

stock to be forged should be less than three times the diameter of the stock.

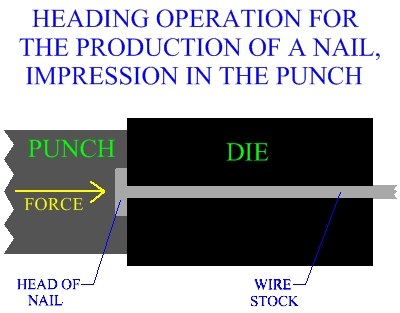

Figure:186

|

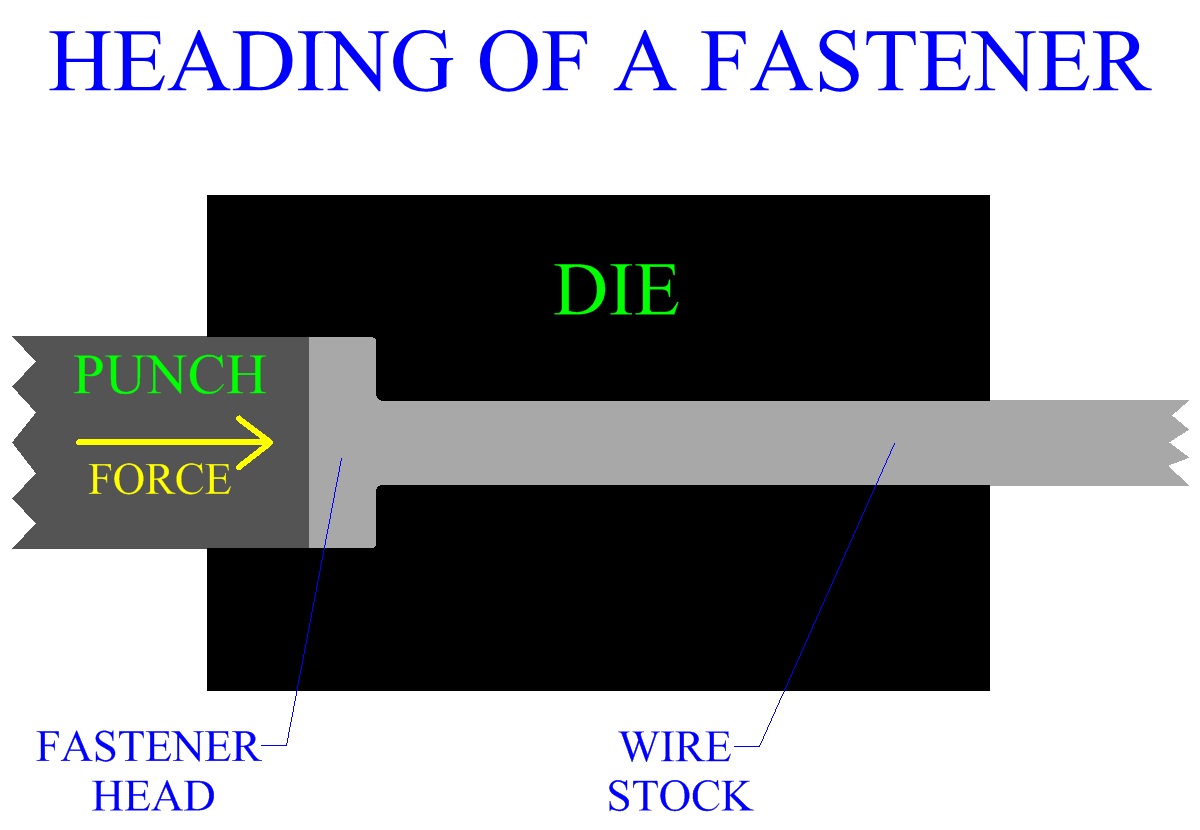

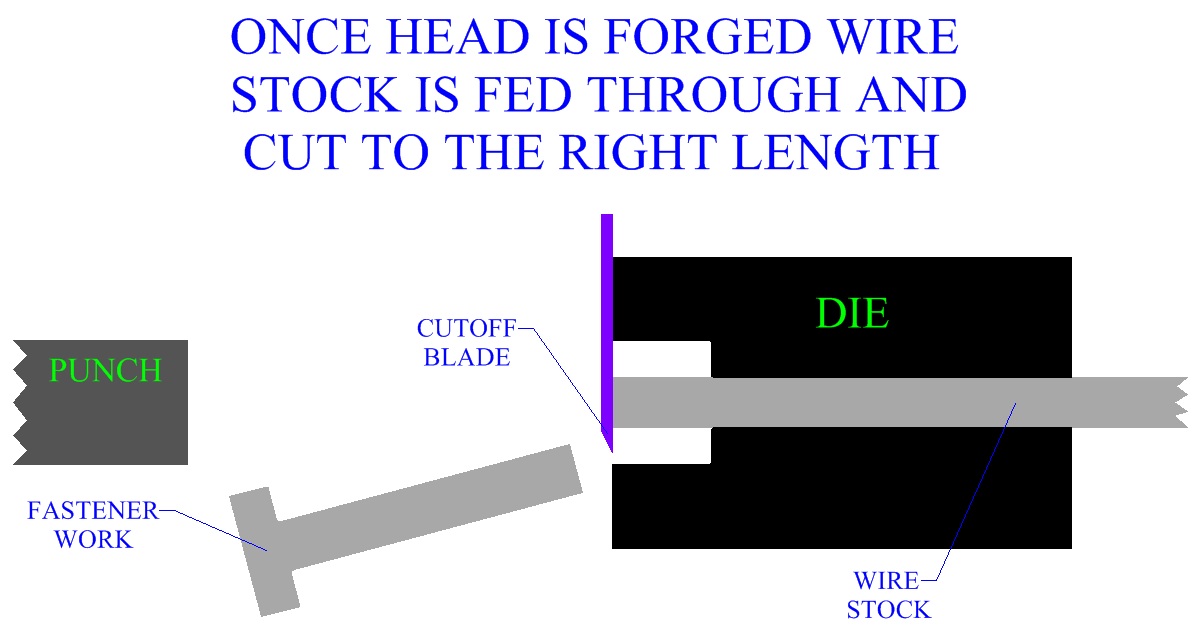

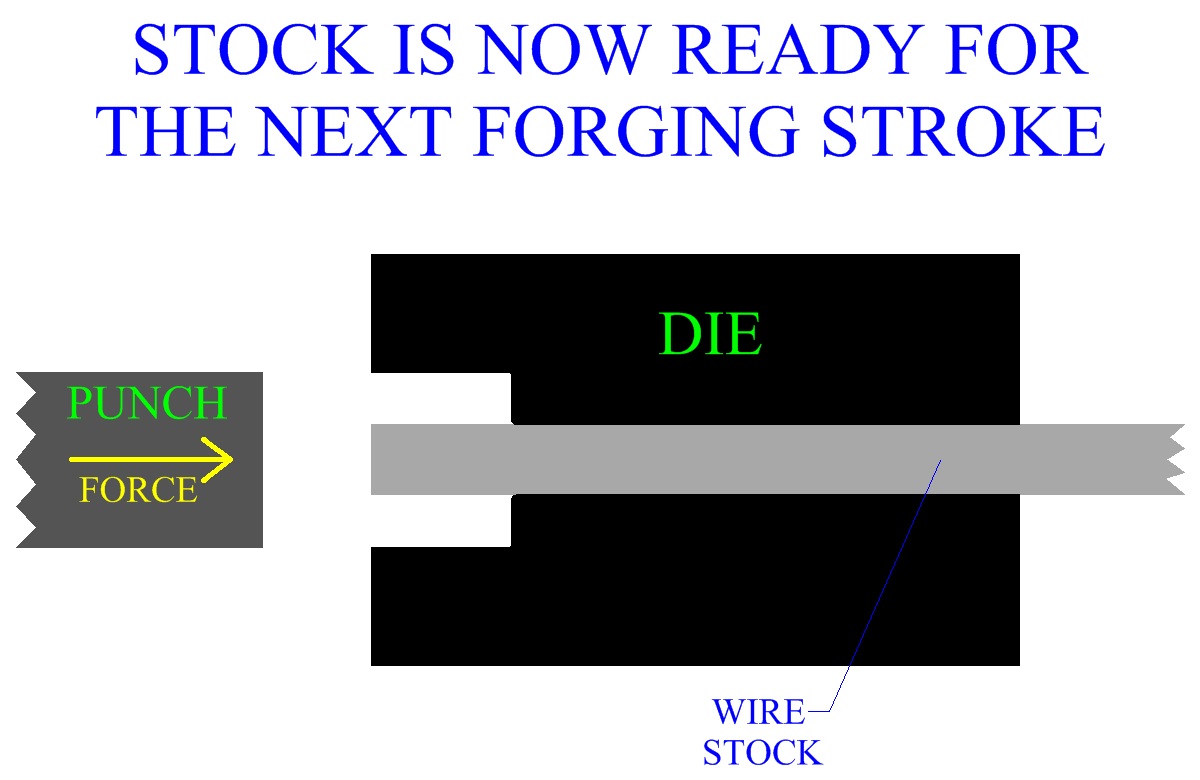

Upset forging, or heading, is a well developed metal working

process in manufacturing industry. Stock is fed through the die, forged, and then cut to length.

Some heading operations can produce up to 300 parts per minute.

Most fasteners will be subject to a further

thread rolling operation to form threads. Thread rolling also has

an extremely high productivity rate.

Figure:187

|

Figure:188

|

Figure:189

|

TOP

|

PRIVACY POLICY

|