Manufacturing Home

FORGING

PROCESSES

Metal Forging

Drop Forging Hammers

Hydraulic And Mechanical Presses

Heading Or Upset Forging

Metal Piercing

Metal Sizing

Roll Forging

Metal Hobbing

Metal Ball Forging

Orbital Forging

Ring Forging

Riveting

Metal Coining

Isothermal Forging

Trimming Of Forged Parts

High Energy Rate Forging

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Rolling

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

|

Metal Swaging

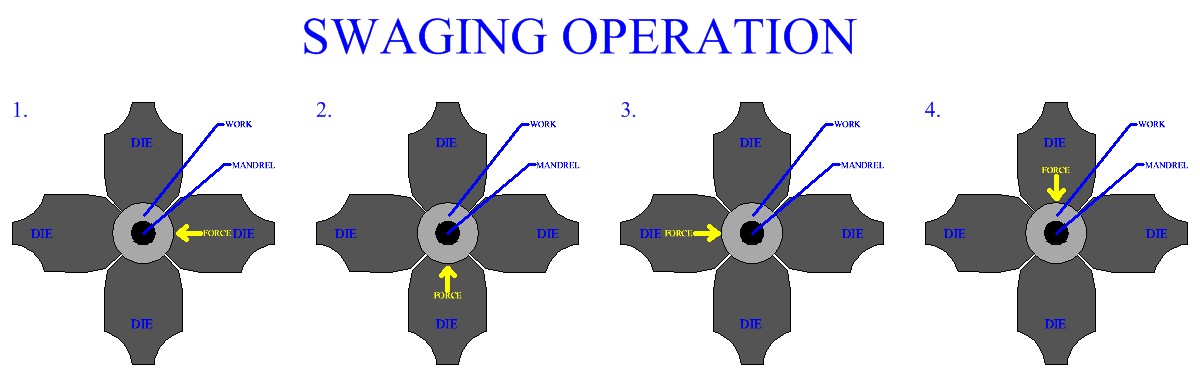

Metal swaging or radial forging involves the forging of a work piece by use

of die that exert compressive forces by impacts that act around the

work's circumference. In manufacturing industry, swaging is usually performed as a cold

working process. In addition to the exterior geometry imparted by the

impacting die, interior part geometry can also be forged by use of a mandrel.

In metal swaging manufacture, the work material is not completely restricted by

the die. This is important to note when considering the metal flow that will

occur during this forging process. Many impacts from each die may be required

to completely forge the work to the geometry of the die and mandrel. In a

typical metal swaging process, the work may receive several forging blows per

second. These forging strokes are performed and coordinated by rollers that

act in a cage. The cage rotates around the part, and the rollers, in turn, enact the

motion of the die.

|

PRIVACY POLICY

|