FORGING PROCESSES Metal Forging Drop Forging Hammers Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Hobbing Metal Ball Forging Orbital Forging Ring Forging Riveting Metal Coining Isothermal Forging Trimming Of Forged Parts High Energy Rate Forging MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Hydraulic And Mechanical Presses

The press represents a specific type of machine tool, essential in the performance of industrial manufacturing processes. Presses deliver energy through a force that acts over a distance or stroke. One important application is in metal forging manufacture. The energy of the press is used to close the die, forging the part within. Press machine tools apply force/energy to the work differently than drop hammers, (that deliver energy to the work through a collision), hammers are the other class of machine tools used to forge metal parts. Drop hammers are covered on the previous page. This page will cover different types of press machines, their function, and capabilities, although it is located in the metal forging section, forging is only one class of manufacturing processes that employ presses.

Press machines are also the primary machine tool used in metal extrusion and sheet metal fabrication processes. Hydraulic and mechanical presses are employed during sheet metal forming to the extent that sheet metal processes, in general, are often referred to as press working. Presses may be used in the manufacture of plastic parts. Machining operations, such as broaching, may also require presses.

Press machine tools vary in size and in the amount of force they can output. The energy from a press is often used to do work requiring a tremendous amount of force, such as a large amount of plastic deformation of a sizable piece of metal. The method and nature by which a press machine will deliver its energy will vary, dependent on its type.

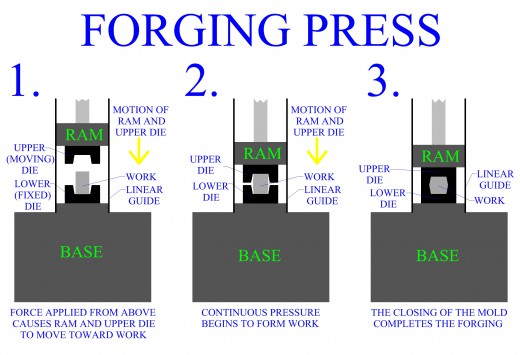

Figure:176

|

Machine presses shown here are vertical, meaning that the force vector is up and down relative to gravity. In many cases these same machine types are utilized horizontally, meaning the force is delivered in a path perpendicular to the direction of the force of gravity. If the force be exerted vertically, horizontally, or at some intermediate angle, the working principles of each type of machine tool are the same.

Press machine tools are of two main types, hydraulic presses and mechanical presses. Selection of a type of machine press depends on the factors of the manufacturing process. The first consideration would be the basic type of process the press tool will be employed to perform. For example, a press for metal forging, a press for extrusion, a press for impact extrusion, or a press for sheet metal working will all have different general requirements. The next very important factor in machine press selection for a manufacturing operation is the press capacity required. Required press capacity is likely related to the size of the work stock, and type of process. Length of stroke over which the press delivers force is another primary factor when choosing a press machine tool, this also will be related to the basic type of process being employed. These initial considerations should give an immediate idea of the general type of press required. After this, all the specific factors of the manufacturing process should be weighed, to determine the best choice for a press machine tool.

Hydraulic Presses

Hydraulic presses are a powerful class of machine tools, they derive the energy they deliver through hydraulic pressure. Fluid pressure, in a particular chamber, can be increased or decreased by the use of pumps, and valves. Sometimes devices and systems may be used to increase the capacity of the pumps in more powerful presses. These presses can operate over a long distance and at a constant speed. Hydraulic presses are generally slower relative to other press machine types. This involves longer contact with the work, therefore the cooling of the work can be an issue when hot forming a part with hydraulic force. Hydraulic presses are capable of being the most powerful class of presses. Some may be as large as buildings, and can deliver awesome pressure. The largest hydraulic presses are capable of applying 75,000 tons, (150,000,000 lbs), of force. The hydraulic press shown is being used to manufacture a metal forging. Extrusion is also a very common use for such a press, although extrusion is often performed horizontally.

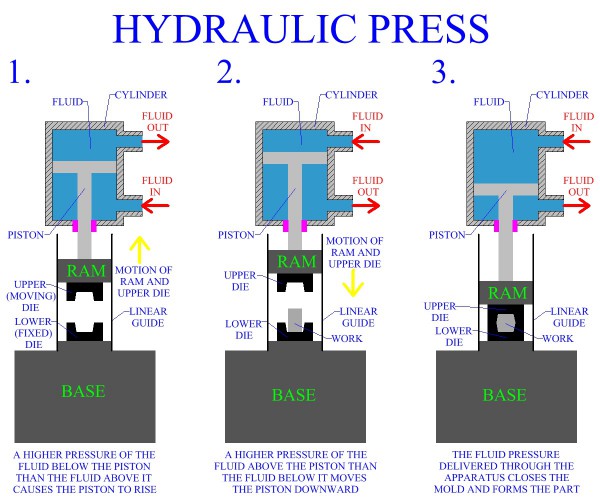

Figure:177

|

The basic working principles of the hydraulic press are simple, and rely on differences in fluid pressure. Fluid is pumped into the cylinder below the piston, this causes the fluid pressure under the piston to increase. Simultaneously, fluid is pumped out of the top channel, causing the fluid pressure above the piston to decrease. A higher pressure of the fluid below the piston than the fluid above it causes the piston to rise. In the next step, fluid is pumped out from below the piston, causing the pressure under the piston to decrease. Simultaneously, fluid is pumped into the cylinder from the top, this increases the fluid pressure above the piston. A higher pressure of the fluid above the piston, than the fluid below it, moves the piston downward.

Mechanical Presses

Mechanical presses belong to a class of machine tools that encompass a wide range of different machine types. Primarily, the mechanical press transforms the rotational force of a motor into a translational force vector that performs the pressing action. Therefore, the energy in a mechanical press comes from the motor. These types of presses are generally faster than hydraulic or screw presses, (actually the screw press may also be classified as a mechanical press). Unlike some presses, in a mechanical press, the application of force varies in both speed and magnitude throughout the distance of the stroke. When performing a manufacturing operation using a mechanical press, the correct range of the stroke is essential.

Presses are chosen based on the characteristics of the manufacturing process. Mechanical press machine tools are commonly used in metal forging manufacture, and sheet metal working. The desired application of force will dictate the type of machine required. Extrusion will often necessitate a more consistent force over a longer distance. However, a mechanical press may often be a good choice for impact extrusion, since a fast, quickly repeatable application of force over a limited distance is what is needed for that type of manufacturing process. The most powerful mechanical presses in modern manufacturing industry will have a press capacity of about 12,000 tons, (24,000,000 lbs).

Crank Press

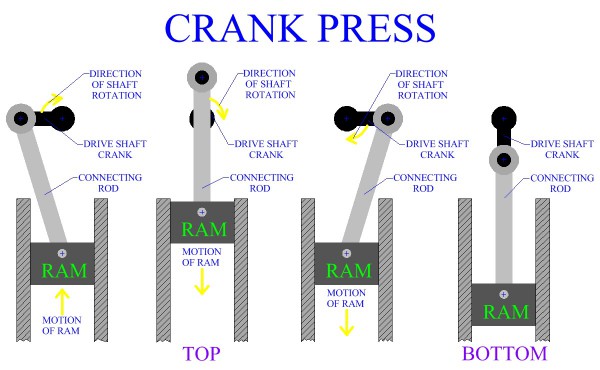

The crank press uses a crank link attached to a drive shaft. The crank link rotates with the drive shaft and is attached to a connecting rod by a rotational joint. The connecting rod rocks back and forth during the motion of the crank. The connecting rod is, in turn, attached to a ram by a rotational joint. The ram operates in a slider joint and travels a one dimensional path in both directions. It is through this path that the crank press delivers its force. The crank press does allow for a stoke of a relatively long distance.

Figure:178

|

Knuckle Joint Press

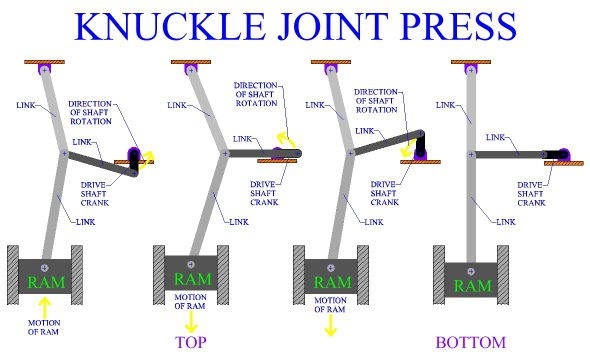

The knuckle joint press translates the energy of a motor through a powerful linkage design, and is capable of delivering a tremendous amount of force. The drive shaft crank rotates completely. The links are well grounded to support such pressure.

Figure:179

|

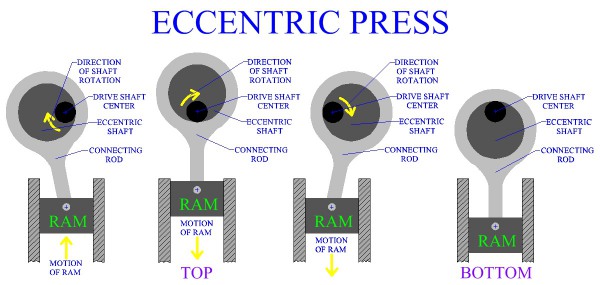

Eccentric Press

The eccentric press uses a motor to drive an eccentric shaft, rotating in a connecting rod. The connecting rod moves a ram in a slider joint one dimensionally. The eccentric shaft itself is round, therefore it may completely rotate within the connecting rod. The center of the drive is not the center of the overall shaft. As the motor rotates, the center of the drive remains stable but the overall center of the shaft changes. This causes the shaft to change position, providing motion. The actual principle of an eccentric press is very similar to a crank press.

Figure:180

|

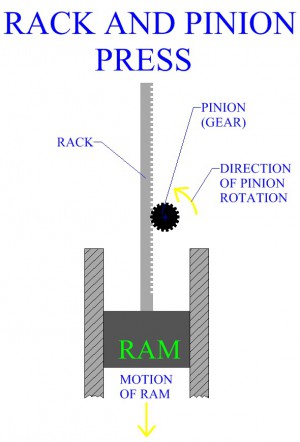

Rack And Pinion Press

The rack and pinion press delivers the motors energy from a gear directly connected to the drive shaft. The rack is actually a round gear of infinite radius. A rotating gear (pinion), provides force through the rack. This gives the one dimensional, translational motion desired of press machines.

Figure:181

|

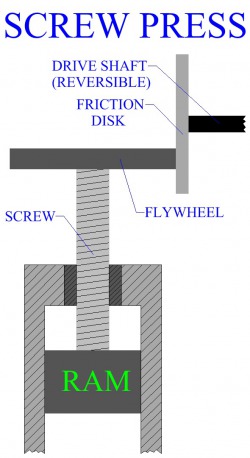

Screw Presses

Screw presses use the rotational energy of a motor to turn a large screw. Typically, a friction disk is used to translate the force from the drive shaft to the screw's head. The screw pushes a ram with great mechanical advantage. Screw presses are similar to hydraulic presses in that they are relatively slow and require a longer contact with the work. Screw presses are also similar to hydraulic presses in that they can produce a constant amount of force over a long stroke. Some screw press machine tools in modern industry can produce 31,000 tons, (62,000,000 lbs), of force.

Figure:182

|