FORGING PROCESSES Metal Forging Drop Forging Hammers Hydraulic And Mechanical Presses Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Hobbing Metal Ball Forging Ring Forging Riveting Metal Coining Isothermal Forging Trimming Of Forged Parts High Energy Rate Forging MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

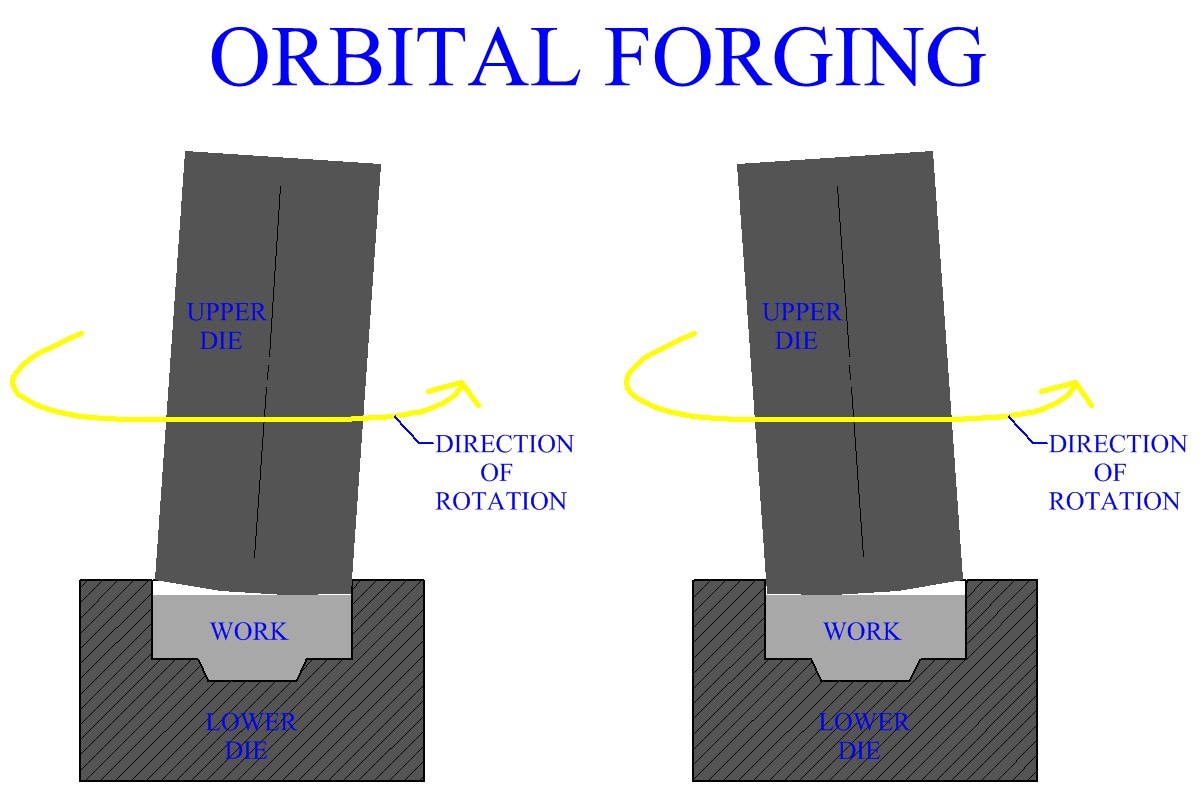

Orbital Forging

Orbital forging is a manufacturing process by which a part is held in a forging die cavity and forged by compressive forces applied through the upper die. The upper die applies these forces as it travels in an orbital path. This upper die revolves on an inclined axis, and thus through its revolution it will only apply force to a small portion of the work at a time. Forging force will be administered to the entirety of the work with the completion of a revolution of the upper die on its inclined orbit.

Figure:200

|

The advantage of orbital forging, (similar to other incremental metal forging processes), is that since only a portion of the work is forged at a time, lower forces are required to perform this process. Another advantage is that this metal forging technique does not produce a lot of noise. Typically in manufacturing practice 10 to 20 revolutions of the upper die will be needed to forge a part. Conical and disk shaped parts, such as gears, are commonly manufactured by orbital forging.