FORGING

PROCESSES

Metal Forging

Drop Forging Hammers

Hydraulic And Mechanical Presses

Heading Or Upset Forging

Metal Piercing

Metal Sizing

Swaging Or Radial Forging

Metal Hobbing

Metal Ball Forging

Orbital Forging

Ring Forging

Riveting

Metal Coining

Isothermal Forging

Trimming Of Forged Parts

High Energy Rate Forging

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Rolling

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

Roll Forging

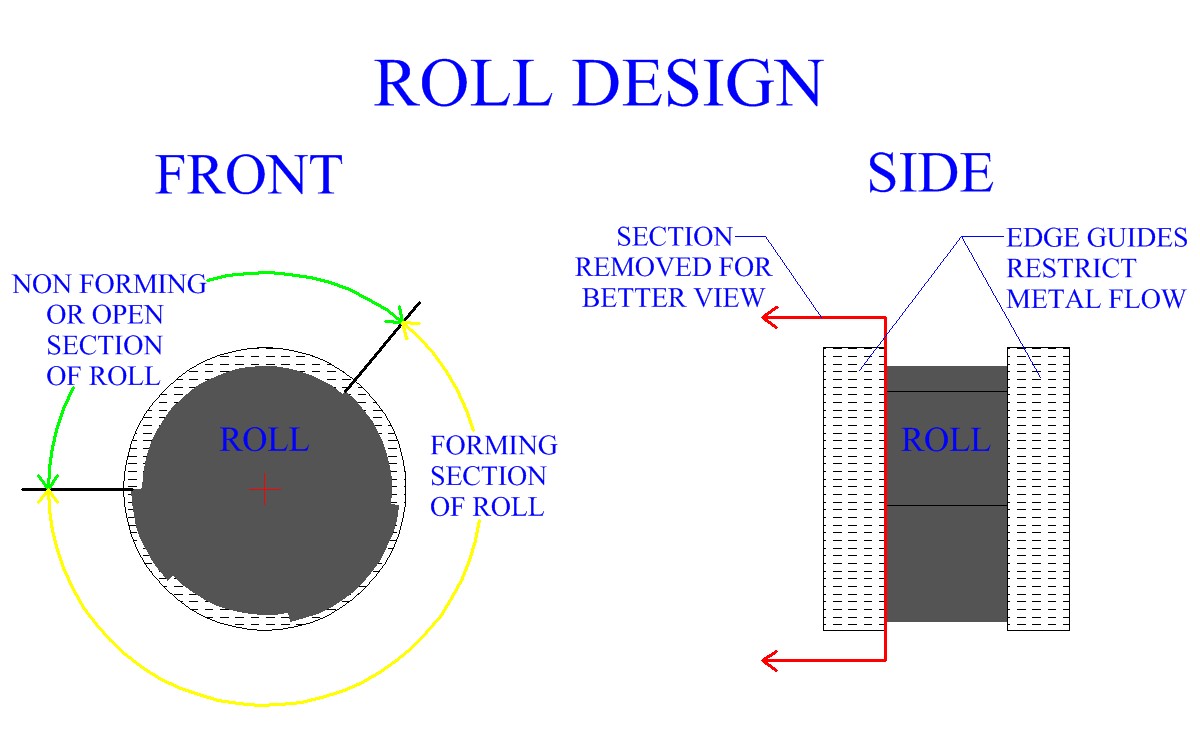

Roll forging or roll forming is a forging technique that utilizes opposing rolls to shape a metal part. Even though roll forging uses rolls in order to accomplish the deformation of the material, it is classified as a metal forging process and not a rolling process. More similarly to metal forging than metal rolling, it is a discrete process and not a continuous one. Roll forging is usually performed hot. The precisely shaped geometry of grooves on the roll, forge the part to the required dimensions. The forging geometry of the rolls used to forge metal parts is only present over a portion of the roll's circumference. Only part of a full revolution of a roll is needed to forge the work piece. Typically in manufacturing industry, the forging geometry on the rolls may occupy from one quarter to three quarters of the roll's circumference.

Figure:192

|

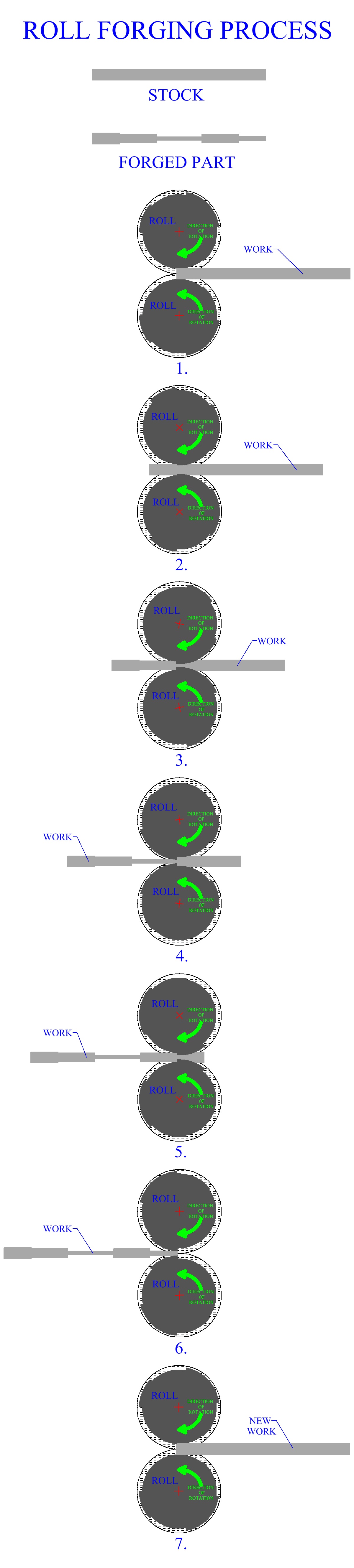

The non grooved portion of the roll's revolution is useful for feeding the stock during the process. Also it can be determined that the length of a work piece that can be metal forged by this manufacturing process, is limited by the size of the rolls and the portion of the rolls over which the forming of the metal occurs. First the work piece is fed into the rolls at the correct place in the roll's revolution. The rolls turn, acting to pull the work into the gap. As the work piece is fed through the grooved portion of the roll's revolution, the compressive forces form the material into the desired shape. The following illustrates the roll forging process.

Figure:193

|

Roll forging manufacture is often used in the automotive industry to manufacture parts. Shafts of various geometries, knives, hand tools and leaf springs, are some products commonly manufactured by this process. Parts created by roll forging possess superior mechanical properties than those produced from many other processes.