FORGING PROCESSES Metal Forging Drop Forging Hammers Hydraulic And Mechanical Presses Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Hobbing Metal Ball Forging Orbital Forging Ring Forging Riveting Metal Coining Isothermal Forging High Energy Rate Forging MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

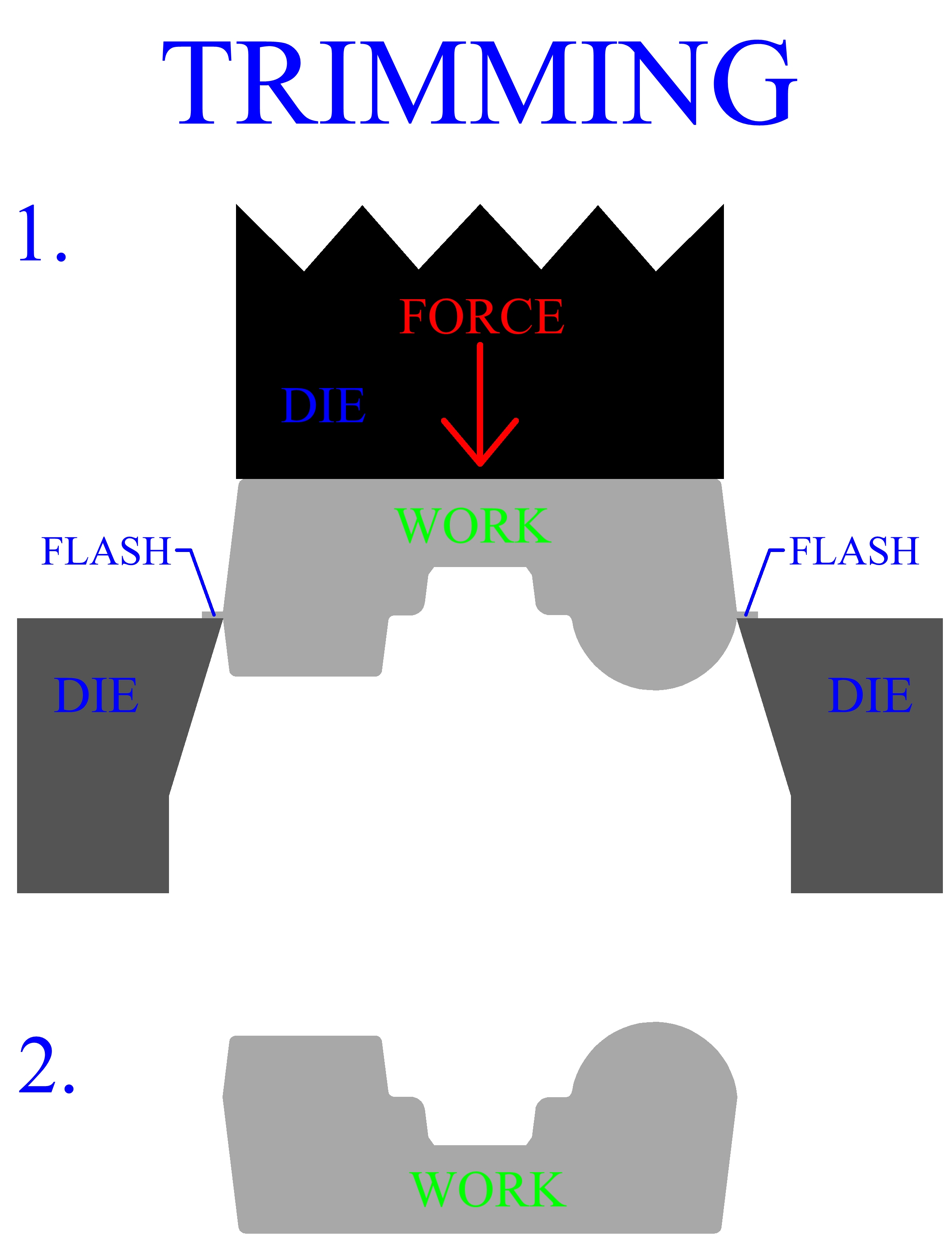

Trimming Of Forged Parts

Trimming is a manufacturing process that is used as a finishing operation for forged parts, in order to remove flash. Flash is a characteristic common in most metal forgings. For that reason trimming, while not technically a forging or even a forming operation in general, is discussed in this section. Trimming basically presses a part through a cutting die that runs the periphery of the work. The cutting die are precisely designed to remove the flash from a particular part. Most often it is desirable to perform this operation while the work is still hot for maximum efficiency, therefore it is usually incorporated into the larger production process. For more delicate forgings, flash can be ground or cut off using different methods. For certain metal forgings, this is an extremely quick and easy method for the removal of the extra material.

Figure:206

|