FORGING

PROCESSES

Metal Forging

Drop Forging Hammers

Hydraulic And Mechanical Presses

Heading Or Upset Forging

Metal Piercing

Metal Sizing

Roll Forging

Swaging Or Radial Forging

Metal Hobbing

Orbital Forging

Ring Forging

Riveting

Metal Coining

Isothermal Forging

Trimming Of Forged Parts

High Energy Rate Forging

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Rolling

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

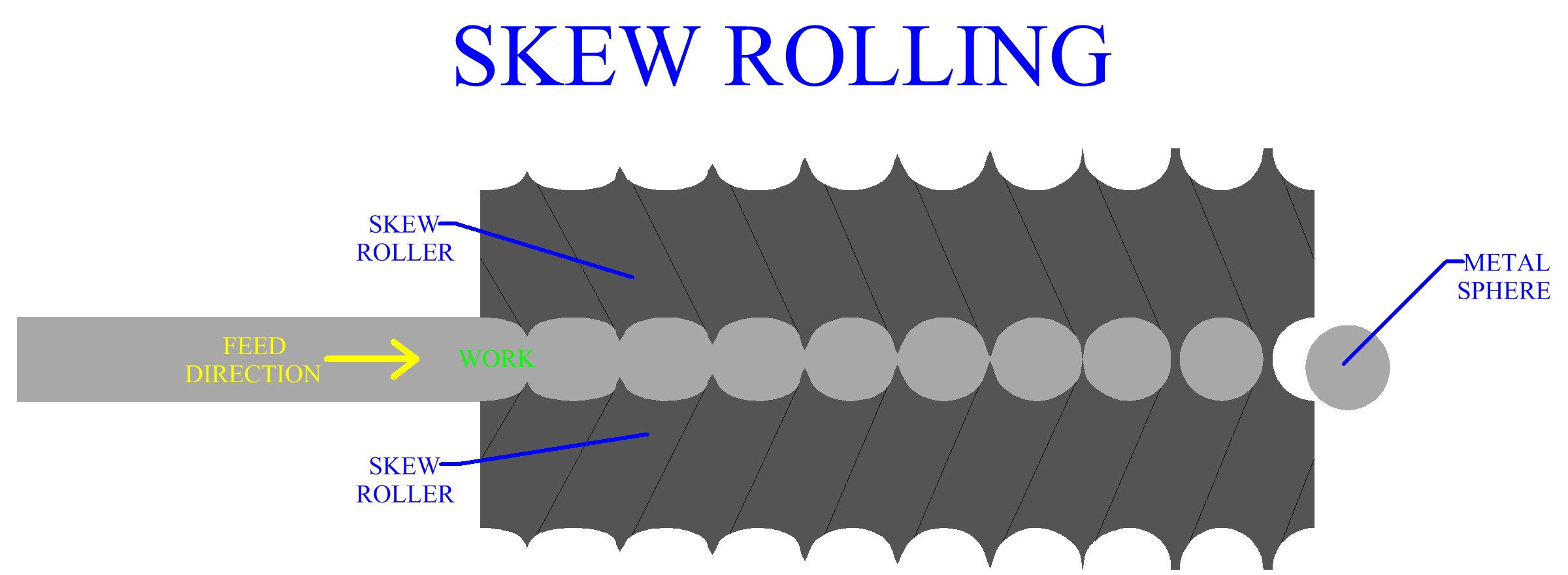

Metal Ball Forging

The ability to manufacture metal spheres with very accurate dimensions and surface quality is important in modern industry. One of the main applications of these metal balls is for use as ball bearings. Ball bearings are widely used in mechanical systems involving the translation of motion. For example, in automobiles or industrial robots, ball bearings are a critical component. In the swaging process, ball bearings are used to time and enact each forging stroke. One of the main ways that these metal spheres are manufactured is by skew rolling. Skew rolling is a metal forging process that uses two specially designed opposing rolls, that rotate continuously. Round stock is fed into the rolls, the material is forged by each of the grooves in the rolls and emerges from the end as a metal ball. The stock is fed through the rolls continuously, but each ball is produced separately, thus it is a discrete process and not a continuous one. Skew rolling, similar to roll forging, is a manufacturing process that bears qualities of both metal rolling and metal forging.

Figure:198

|

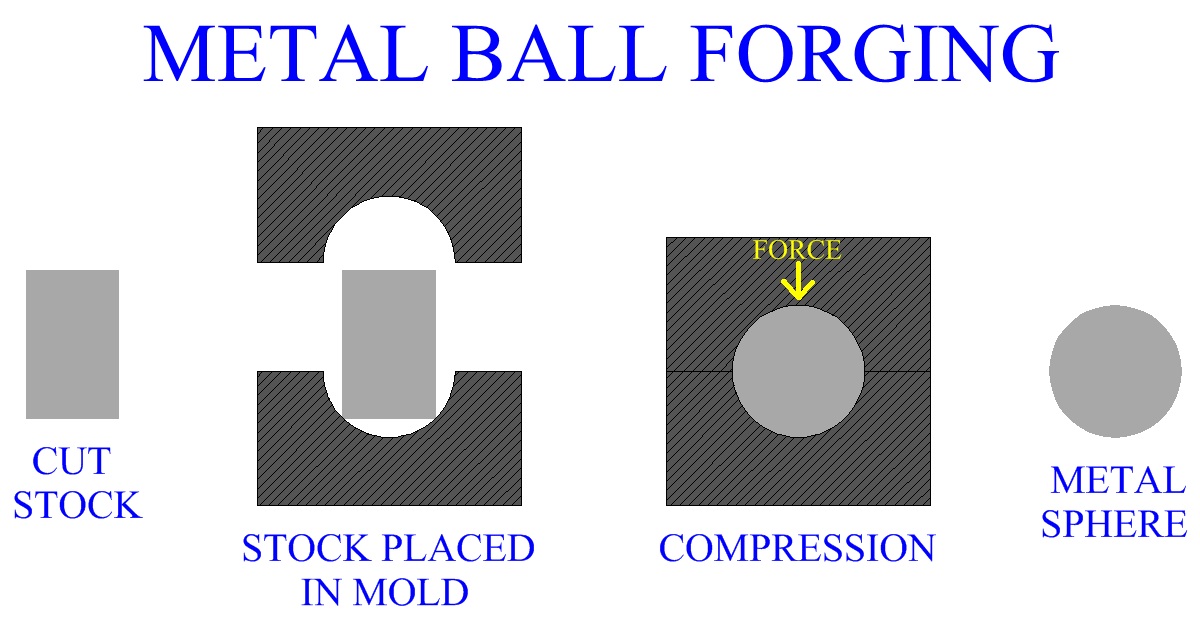

Another method of producing metal spheres is by forging them in a mold. A work piece is cut from stock and placed in the die. The die are forced together, forging the metal ball, causing it to take the spherical shape of the die cavity. Balls are finished and polished, before they are ready for their particular application.

Figure:199

|