METAL CASTING PROCESSES Metal Casting Principles Metal Casting Metal Casting Operation Effect Of Gases On Metal Casting Metal Casting Design Expendable Mold Casting Sand Casting Plaster Mold Casting Ceramic Mold Casting Shell Mold Casting Vacuum Casting or V-process Expanded Polystyrene Casting Investment Casting Permanent Mold Casting Basic Permanent Mold Casting Slush Casting Pressure Casting Vacuum Permanent Mold Casting Die Casting Hot Die Casting Cold Die Casting True Centrifugal Casting Semicentrifugal Casting Ingot Casting Continuous Casting MANUFACTURING PROCESSES Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Centrifuge Casting

Centrifuge casting is the third main branch of centrifugal casting processes used for industrial manufacture of cast parts. For more detailed information on the other two manufacturing processes that fit into the category of centrifugal casting see, true centrifugal casting and semicentrifugal casting. Developing an understanding of these techniques will greatly assist in learning about centrifuge casting, since the main principles that govern centrifuge casting are the same for all centrifugal casting processes. Centrifuge casting is different in that castings manufactured by the centrifuge casting process need not have rotational symmetry. With centrifuge casting, metal castings of desired shapes can be manufactured with all the distinct benefits of castings produced by a centrifugal casting process.

The Process

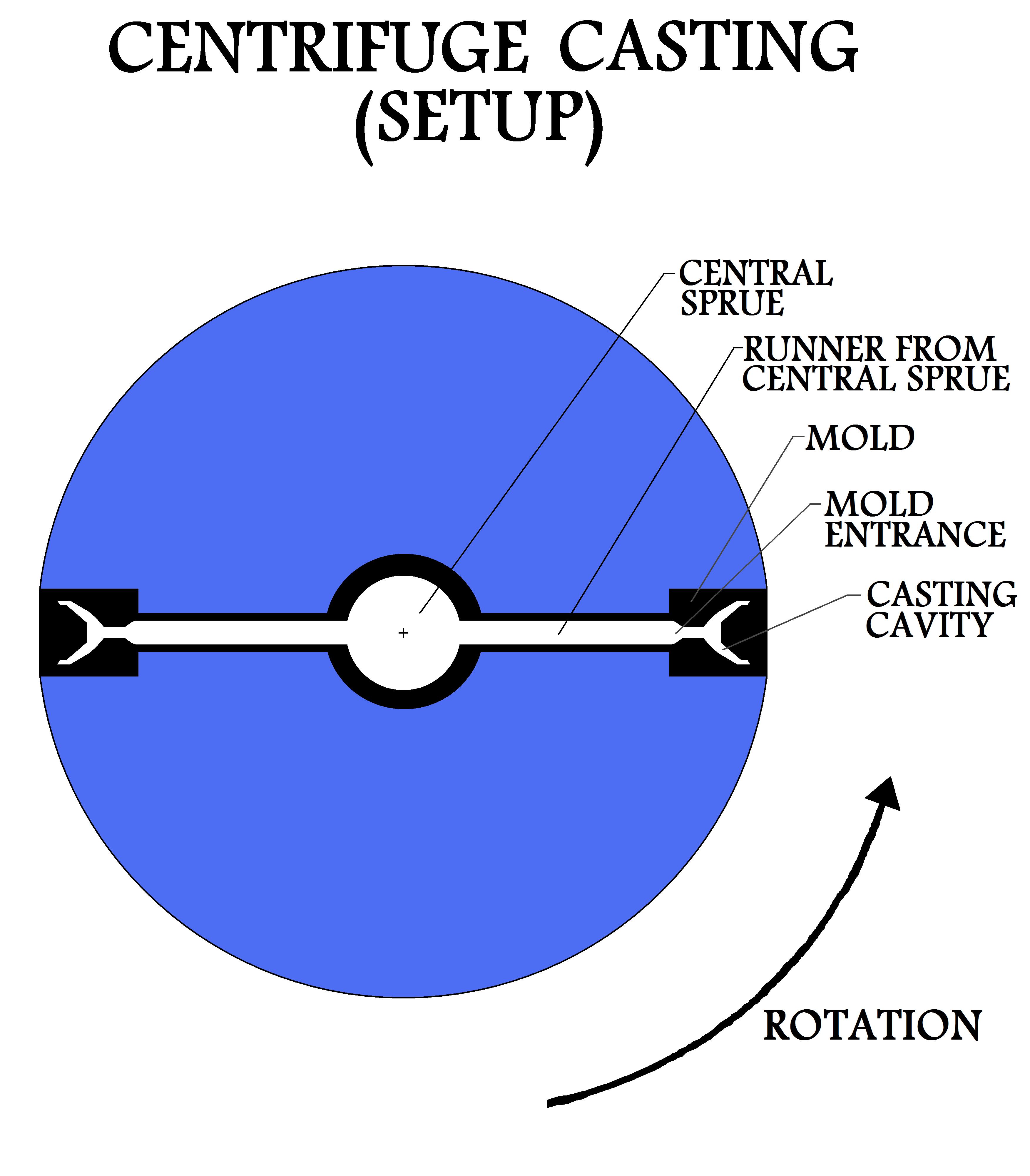

In centrifuge casting manufacture, molds employed to produce the desired castings are arranged around a central sprue. These molds contain all the necessary geometry for the cast part, as well as the gating system. Runners travel from the central sprue to the mold entrances.

Figure:105

|

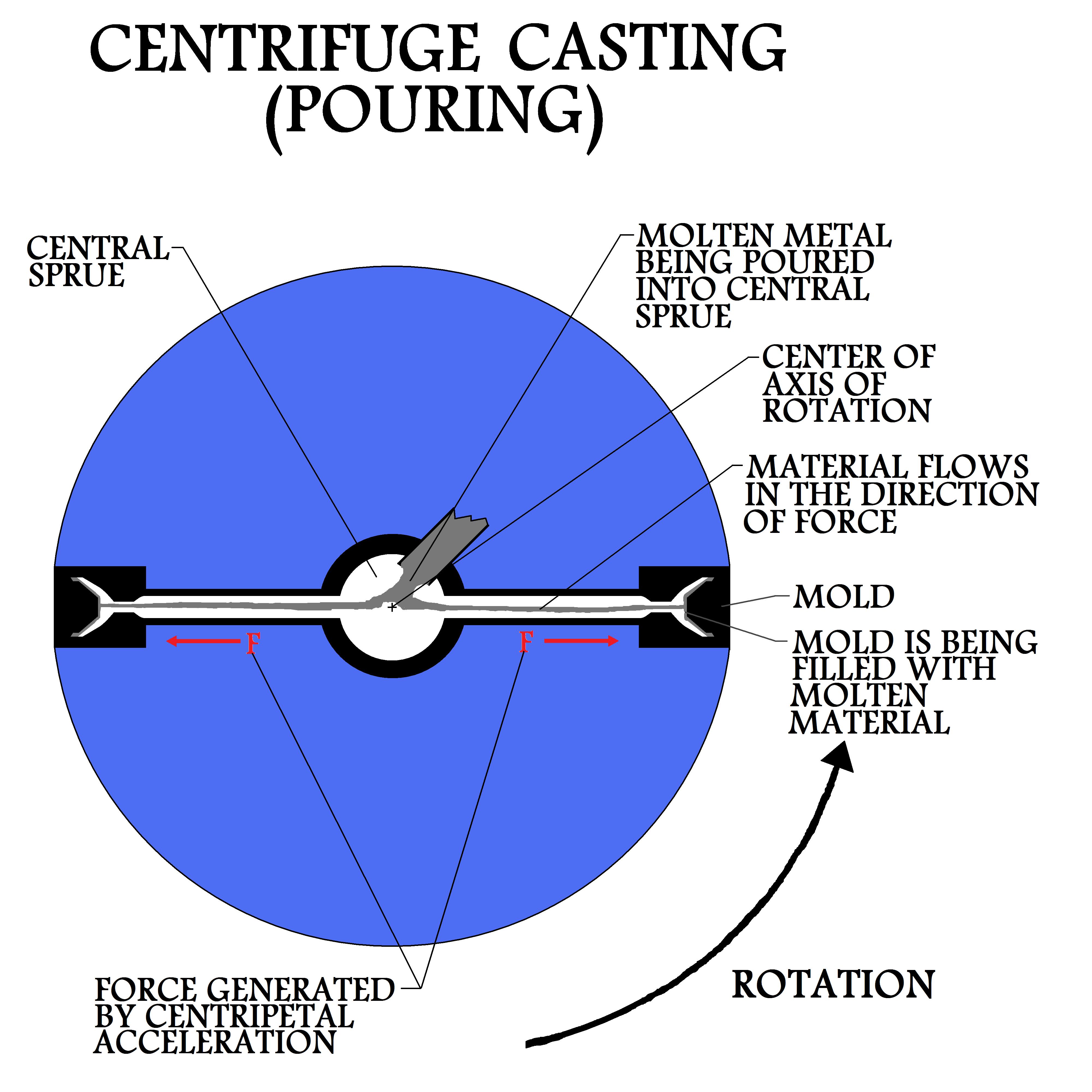

During the pouring phase of centrifuge casting manufacture, molten material is introduced into the central sprue. The entire system is rotated about an axis with the central sprue at the center of rotation. When an object is rotated, forces are produced that act directly away from the center of the axis of rotation. It would be known from the previous discussions concerning the other two branches of centrifugal casting, that the utilization of the forces of centripetal acceleration which act to push material away from the center of rotation is the trademark characteristic of all the manufacturing processes of centrifugal casting. Centripetal force is not only utilized to distribute molten material through a mold, but to help control the material properties of a cast part.

In centrifuge casting manufacture, the molten material to produce the casting is poured into the central sprue. Centripetal forces from the rotating apparatus push this material outward from the center, through the runners and into the molds.

Figure:106

|

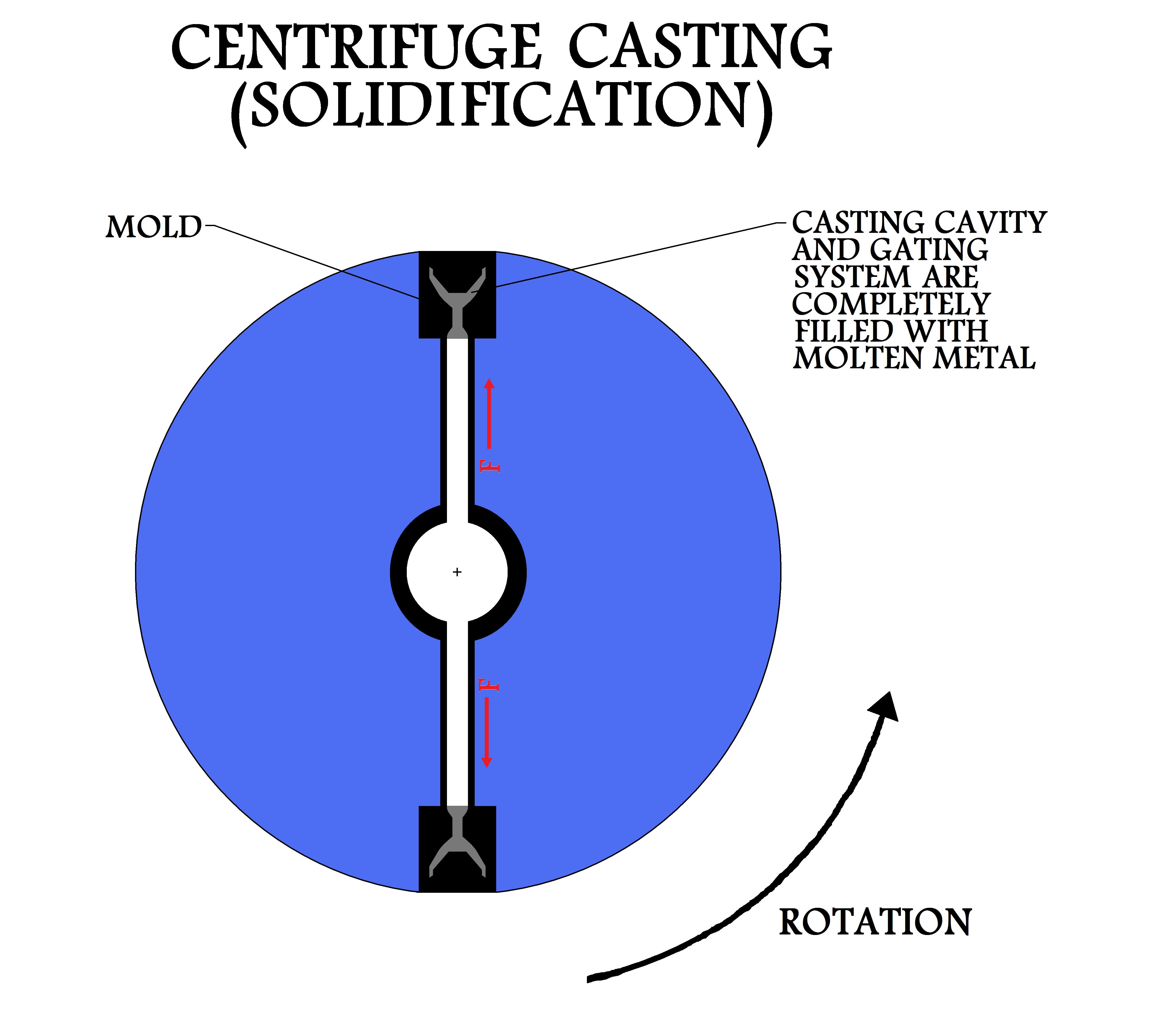

When the correct amount of molten metal to manufacture the casting is poured and distributed completely into the molds, the apparatus will continue to rotate as solidification is occurring.

Figure:107

|

After the castings have completely solidified, the apparatus will stop rotating and the parts can be removed.

Centrifuge Casting Manufacture

There are many specific advantages in the quality of parts manufactured by centrifuge casting. Since the metal is forced into the mold, the mold cavity usually fills completely and cast parts with thin walled sections are possible. Also, great surfaces can be produced by centrifugal casting, which is another characteristic of castings manufactured by a process that uses large amounts of force to fill a mold.

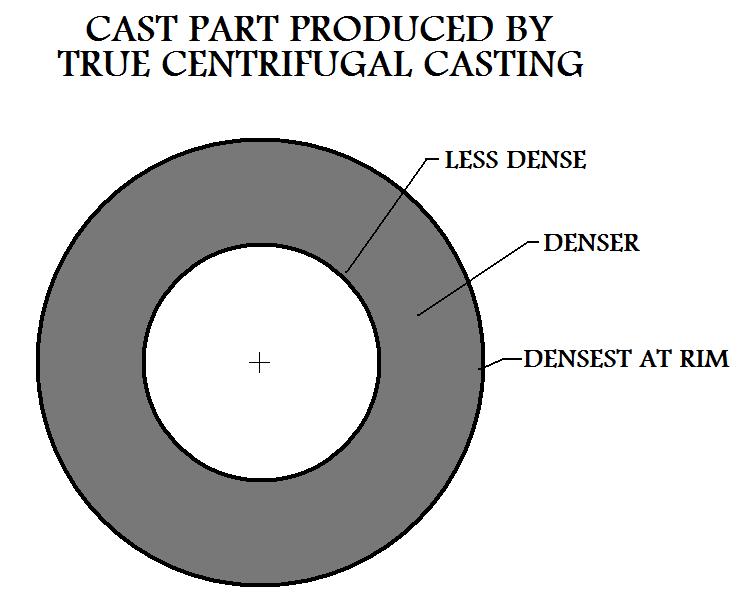

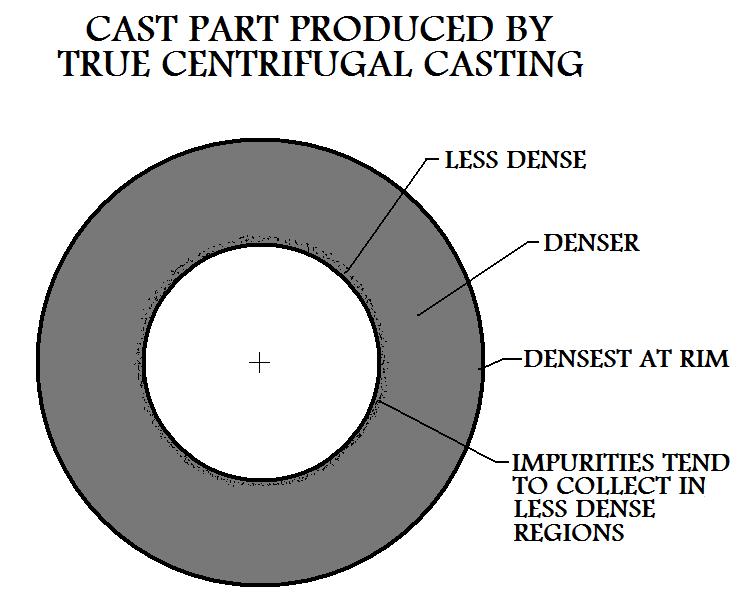

One of the most notable features, specific to the centrifugal casting processes and discussed in the preceding sections, is the effect of centripetal forces acting continuously on the material as the casting solidifies. Molten material that solidified under greater force will be denser than the same material that solidified under less force. This can be observed in a round cylinder manufactured using the true centrifugal casting process.

Figure:108

|

During the solidification of this part the mold was rotating. The forces acting on the material farther from the center were greater than the forces that were acting on the material closer to the center. Consequently, it can be seen in the manufactured part that the density is greatest in the outer regions and decreases towards the center.

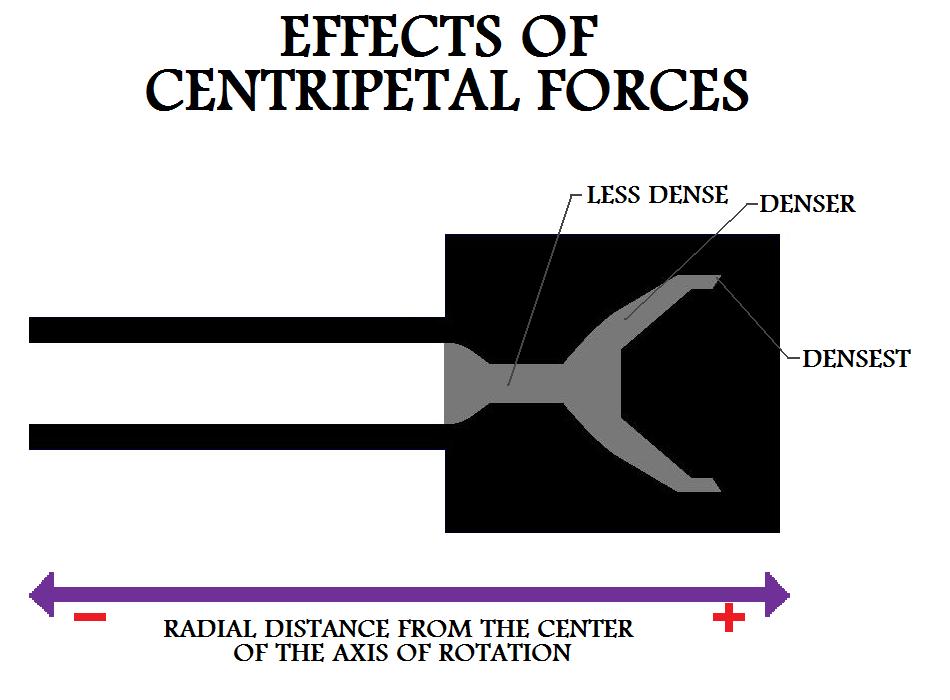

Another specific effect that the centripetal forces used in centrifugal casting methods have on the material of a cast part is that impurities, such as inclusions and trapped air, tend to collect and solidify in the less dense material closer to the center of the axis of rotation.

Figure:109

|

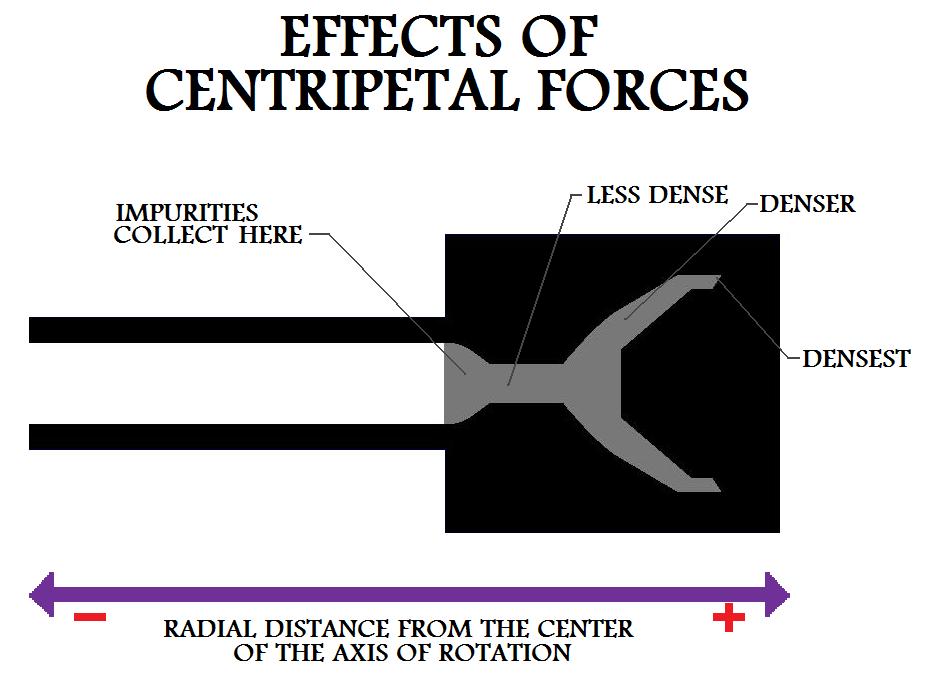

This happens because the material itself is denser than these impurities, when subject to centripetal forces the denser metal pushes to the outer regions, forcing the lighter impurities to the less dense inner regions. These effects of centripetal forces on a casting can be observed not only in cast cylindrical tubes but also in all the wide variety of parts that can be manufactured using the centrifuge casting process as well.

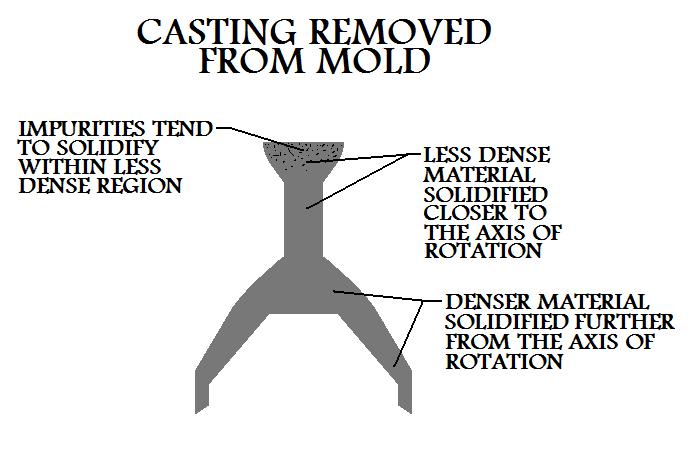

Figure:110

|

It can be seen that the density of the material varies throughout the cast part. The least dense section of the part will be the section that was closest to the center of rotation. The density of the material of the casting will increase with increasing radial distance from the center. Also, impurities that were present in the metal will have collected in the areas of the casting closest to the center of rotation.

Figure:111

|

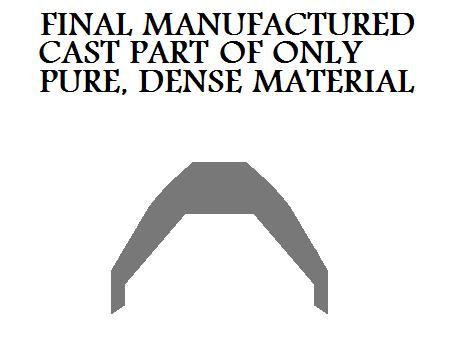

In a carefully planned centrifuge casting operation, the cast part can be designed to be manufactured in such a way that the less dense region containing the inclusions is removed after the production of the casting. This will create a finished part of pure, dense material.

Figure:112

|

Figure:113

|