METAL CASTING PROCESSES Metal Casting Principles Metal Casting Metal Casting Operation Effect Of Gases On Metal Casting Metal Casting Design Expendable Mold Casting Sand Casting Plaster Mold Casting Ceramic Mold Casting Shell Mold Casting Vacuum Casting or V-process Expanded Polystyrene Casting Investment Casting Permanent Mold Casting Basic Permanent Mold Casting Slush Casting Pressure Casting Vacuum Permanent Mold Casting Die Casting Hot Die Casting True Centrifugal Casting Semicentrifugal Casting Centrifuge Casting Ingot Casting Continuous Casting MANUFACTURING PROCESSES Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Cold Die Casting

Cold chamber die casting is the second of the two major branches of the die casting manufacturing process. This section will discuss cold chamber die casting specifically and contrast it with the hot chamber process discussed previously. For a basic view of die casting in general see die casting manufacture.

Cold Chamber Process

Cold chamber die casting is a permanent mold metal casting process. A reusable mold, gating system and all, is employed. It is most likely machined precisely from two steel blocks. Large robust machines are used to exert the great clamping force necessary to hold the two halves of the mold together against the tremendous pressures exerted during the manufacturing process.

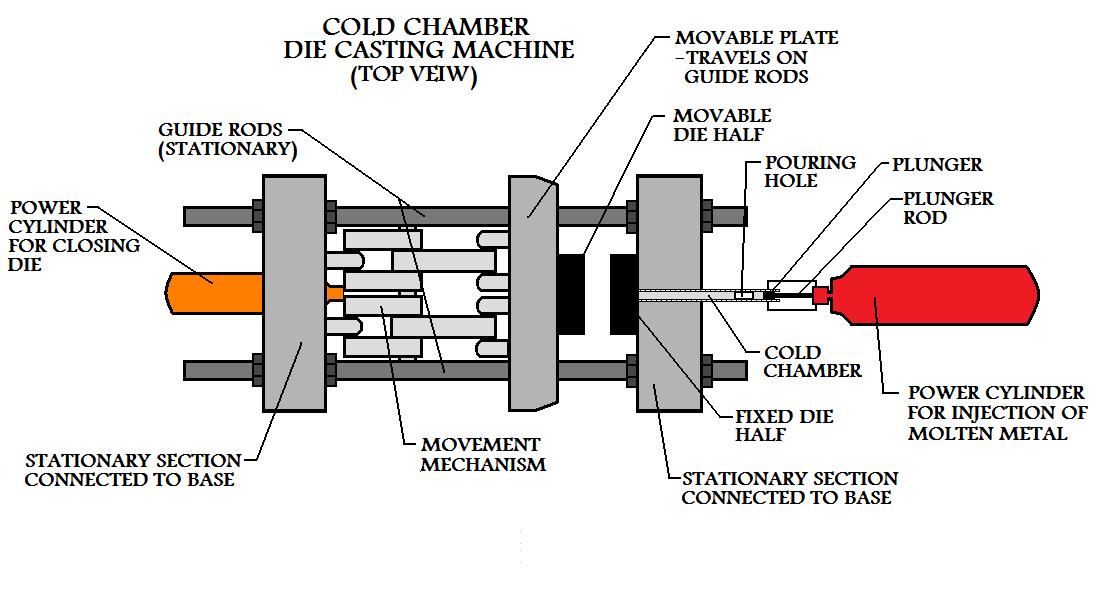

Figure:87

|

A metal shot chamber, (cold-chamber), is located at the entrance of the mold. A piston is connected to this chamber, which in turn is connected to a power cylinder.

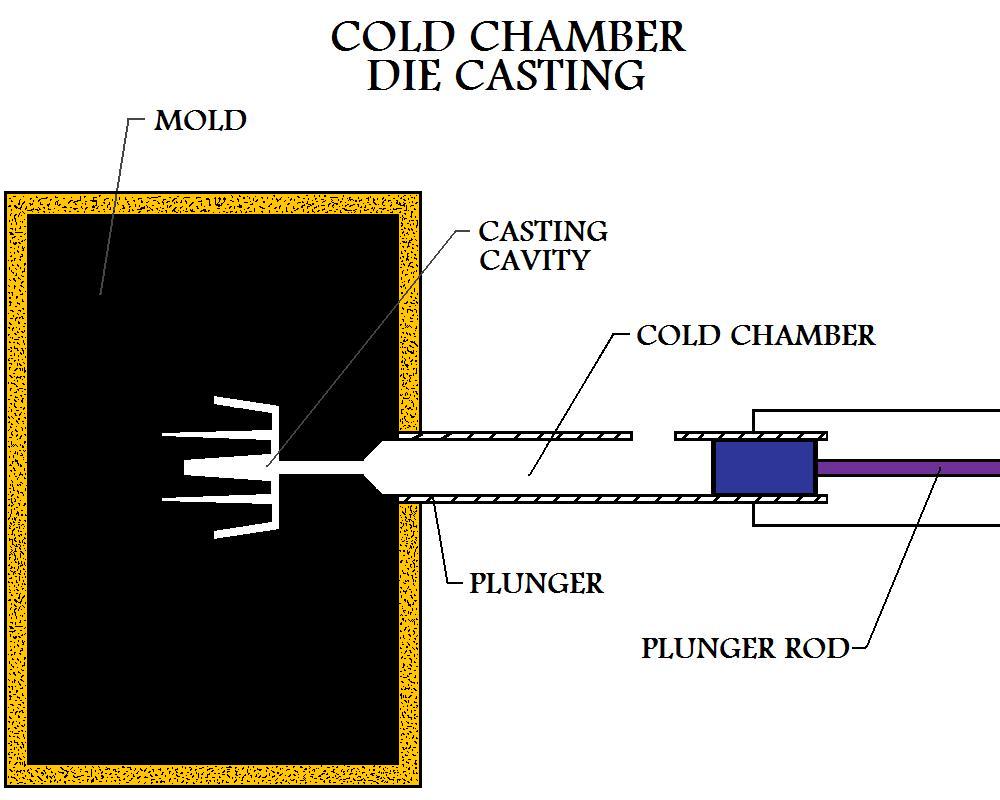

Figure:88

|

At the start of the manufacturing cycle, the correct amount of molten material for a single shot is poured into the shot chamber from an external source holding the material for the metal casting.

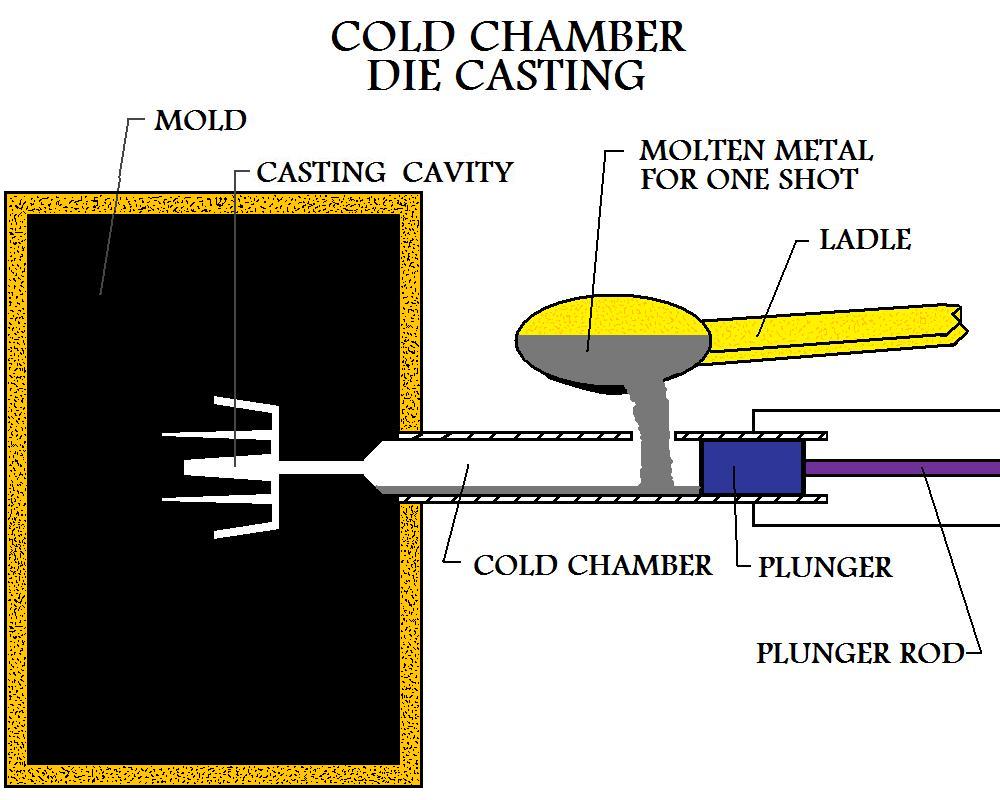

Figure:89

|

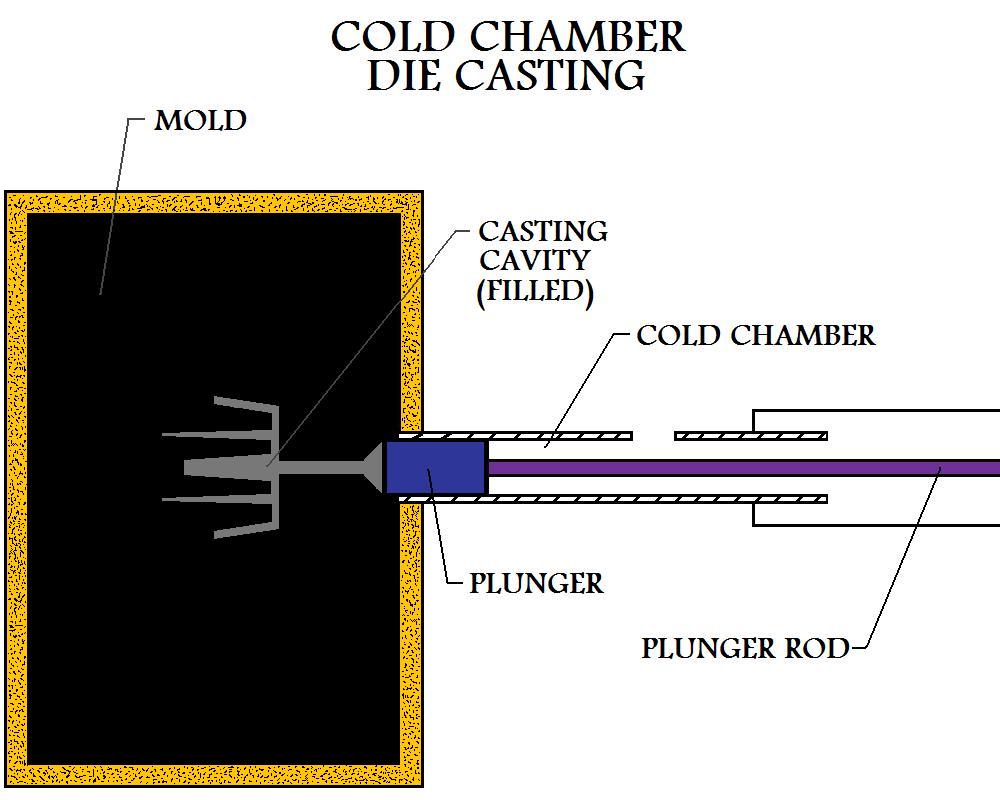

The power cylinder forces the piston forward in the chamber, cutting off the intake port. The power cylinder moving the piston forward forces the molten material into the casting mold with great pressure. Pressure causes the liquid metal to fill in even thin sections of the metal casting and press the mold walls for great surface detail. The pressure is maintained some time after the injection phase of die casting manufacture.

Figure:90

|

Once the metal casting begins to solidify, the pressure is released. Then the mold is opened and the casting is removed by way of ejector pins. The mold is sprayed with lubricant before closing again, and the piston is withdrawn in the shot chamber for the next cycle of production.

Cold Chamber Die Casting For Manufacture

The main difference between cold-chamber die casting and hot-chamber die casting manufacture is that in the cold-chamber process the molten metal for the casting is introduced to the shot chamber from an external source, while in the hot chamber process the source of molten material is attached to the machine. In the hot-chamber process, certain machine apparatus is always in contact with molten metal. For this reason, higher melting point materials will create a problem for the machinery in a hot-chamber metal casting setup. Since the liquid metal is brought in from an outside source, the die casting machinery is able to stay much cooler in a cold-chamber process.

Consequently, higher melting point alloys of aluminum, brass, copper, and aluminum-zinc are often metal cast in manufacturing industry using cold chamber die casting. It is very possible to manufacture castings from lower melting point alloys using the cold-chamber method. When considering industrial metal casting manufacture, however, the advantages of production by the hot-chamber process usually make it the more suitable choice for lower melting point alloys.

In the cold chamber die casting process, material must be brought in for every shot or cycle of production. This slows down the production rate for metal casting manufacture. Where in the hot chamber process, castings can be constantly output. Cold chamber die casting should still be considered a high production manufacturing process.

In comparison with the hot die casting process, the cold die casting process requires the application of more pressure. The pressure at which the molten metal is forced into and fills the die cavity in cold chamber metal casting manufacture typically outranks the pressure used to fill the die in hot chamber metal casting by about an order of magnitude. Pressures of 3000psi to 50000psi (20MPa to 350MPa) may be used in manufacturing industry to fill the mold cavities with molten material during cold chamber die casting manufacture. Castings manufactured by cold chamber die casting have all the advantages characteristic of the die casting process, such as intricate detail, thin walls, and superior mechanical properties. The significant initial investment into this manufacturing process makes it suitable for high production applications.