METAL CASTING PROCESSES Metal Casting Principles Metal Casting Metal Casting Operation Effect Of Gases On Metal Casting Metal Casting Design Expendable Mold Casting Sand Casting Plaster Mold Casting Ceramic Mold Casting Shell Mold Casting Vacuum Casting or V-process Expanded Polystyrene Casting Permanent Mold Casting Basic Permanent Mold Casting Slush Casting Pressure Casting Vacuum Permanent Mold Casting Die Casting Hot Die Casting Cold Die Casting True Centrifugal Casting Semicentrifugal Casting Centrifuge Casting Ingot Casting Continuous Casting MANUFACTURING PROCESSES Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Investment Casting

Investment casting is a manufacturing process in which a wax pattern is coated with a refractory ceramic material. Once the ceramic material is hardened its internal geometry takes the shape of the casting. The wax is melted out and molten metal is poured into the cavity where the wax pattern was. The metal solidifies within the ceramic mold and then the metal casting is broken out. This manufacturing technique is also known as the lost wax process. Investment casting was developed over 5500 years ago and can trace its roots back to both ancient Egypt and China. Parts manufactured in industry by this process include dental fixtures, gears, cams, ratchets, jewelry, turbine blades, machinery components and other parts of complex geometry.

The Process

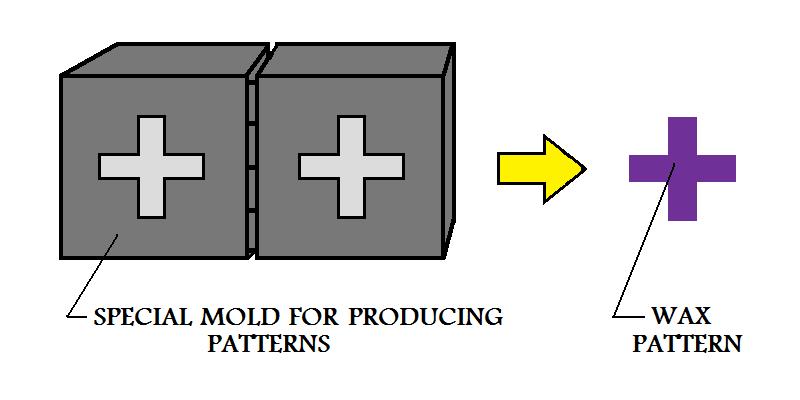

The first step in investment casting is to manufacture the wax pattern for the process. The pattern for this process may also be made from plastic; however it is often made of wax since it will melt out easily and wax can be reused. Since the pattern is destroyed in the process, one will be needed for each casting to be made. When producing parts in any quantity, a mold from which to manufacture patterns will be desired. Similar to the mold that may be employed in the expanded polystyrene casting process to produce foam polystyrene patterns, the mold to create wax patterns may be cast or machined. The size of this master die must be carefully calculated. It must take into consideration shrinkage of wax, shrinkage of the ceramic material invested over the wax pattern and shrinkage of the metal casting. It may take some trial and error to get just the right size, therefore these molds can be expensive.

Figure:48

|

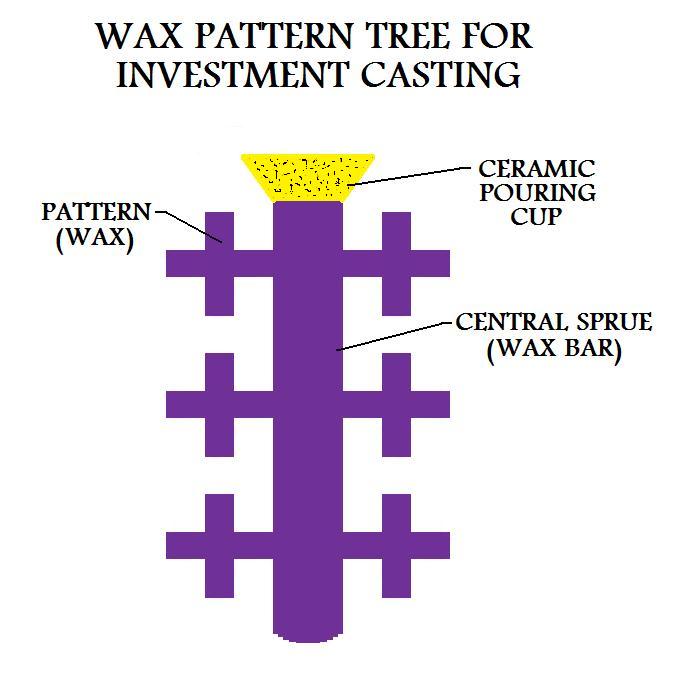

Since the mold does not need to be opened, castings of very complex geometry can be manufactured. Several wax patterns may be combined for a single casting. Or as often the case, many wax patterns may be connected and poured together producing many castings in a single process. This is done by attaching the wax patterns to a wax bar, the bar serves as a central sprue. A ceramic pouring cup is attached to the end of the bar. This arrangement is called a tree, denoting the similarity of casting patterns on the central runner beam to branches on a tree.

Figure:49

|

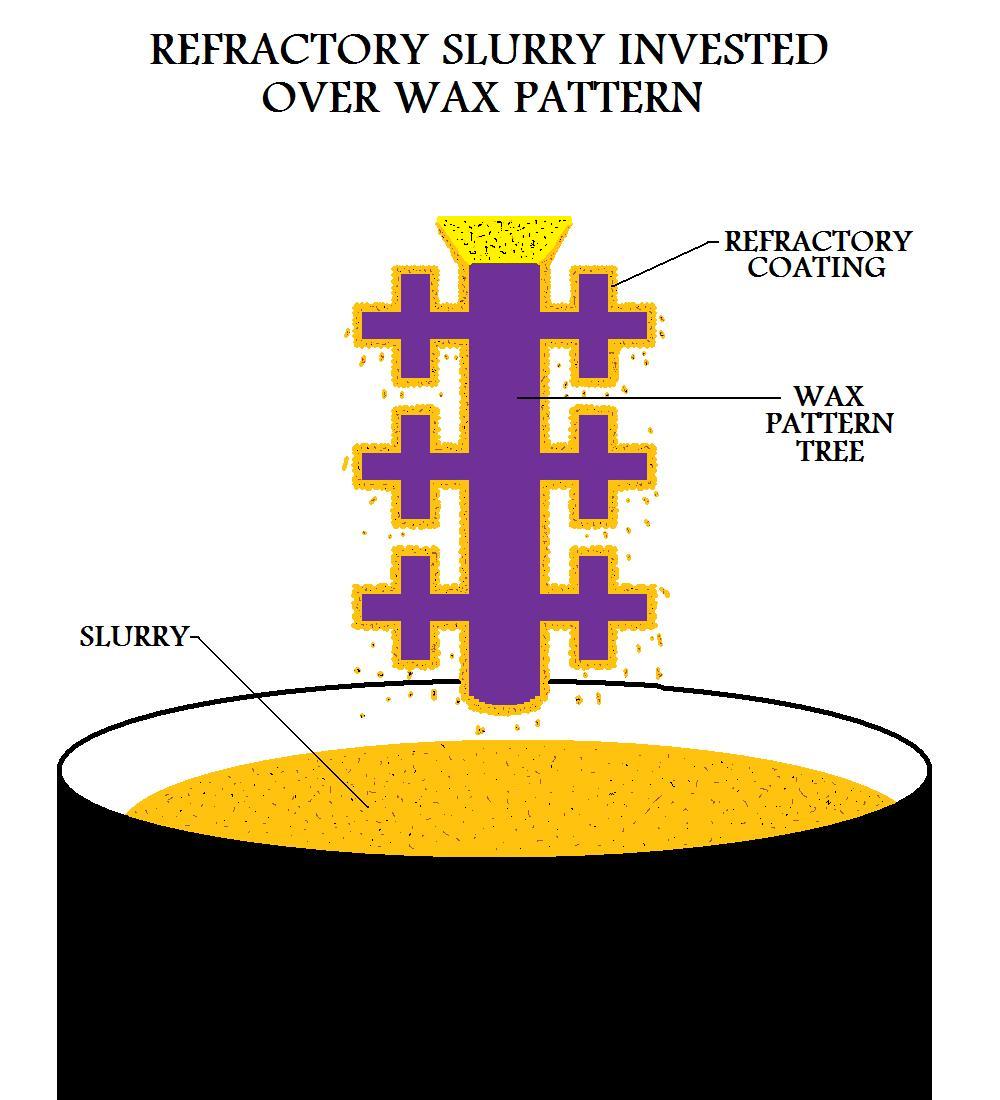

The metal casting pattern is then dipped in a refractory slurry whose composition includes extremely fine grained silica, water and binders. A ceramic layer is obtained over the surface of the pattern. The pattern is then repeatedly dipped into the slurry to increase the thickness of the ceramic coat. In some cases the pattern may be placed in a flask and the ceramic slurry poured over it.

Figure:50

|

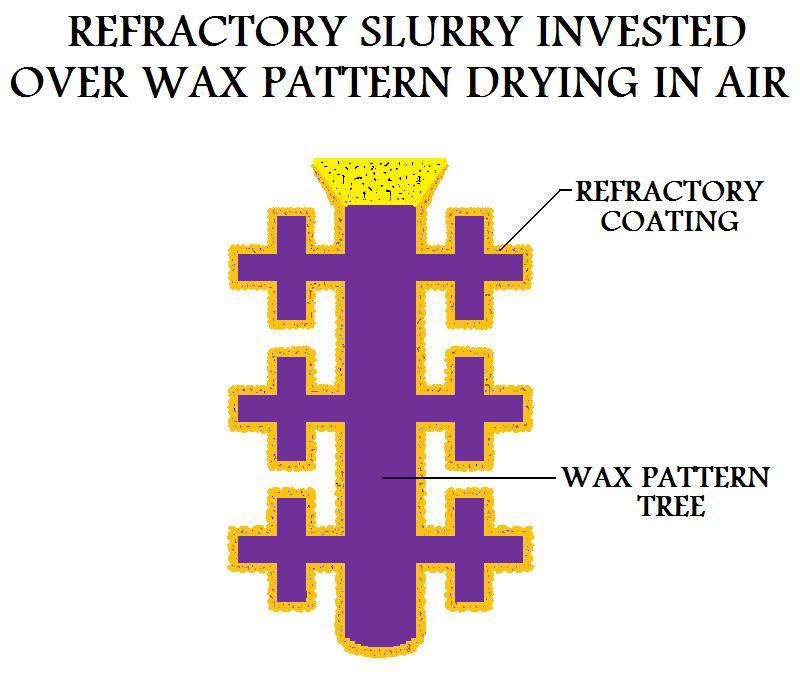

Once the refractory coat over the pattern is thick enough, it is allowed to dry in air in order to harden.

Figure:51

|

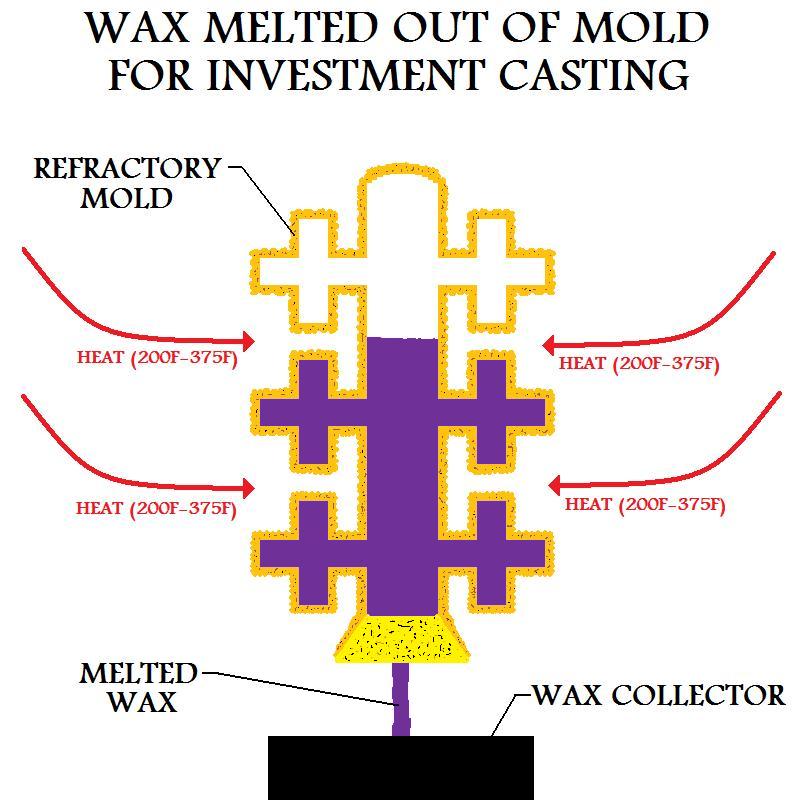

The next step in this manufacturing process is the key to investment casting. The hardened ceramic mold is turned upside down and heated to a temperature of around 200F-375F (90C-175C). This causes the wax to flow out of the mold, leaving the cavity for the metal casting.

Figure:52

|

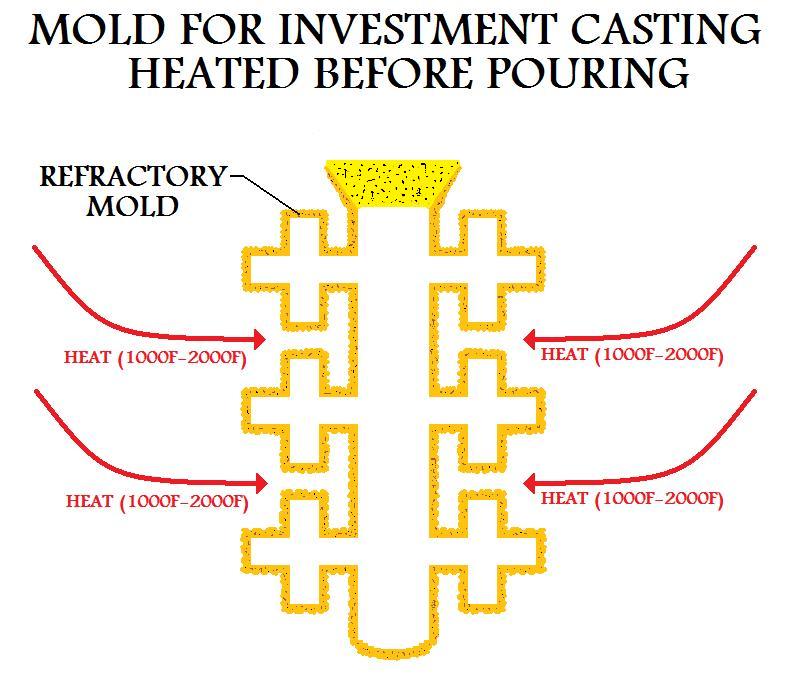

The ceramic mold is then heated to around 1000F-2000F (550C-1100C). This will further strengthen the mold, eliminate any leftover wax or contaminants and drive out water from the mold material. The metal casting is then poured while the mold is still hot. Pouring the casting while the mold is hot allows the liquid metal to flow easily through the mold cavity, filling detailed and thin sections. Pouring the metal casting in a hot mold also gives better dimensional accuracy, since the mold and casting will shrink together as they cool.

Figure:53

|

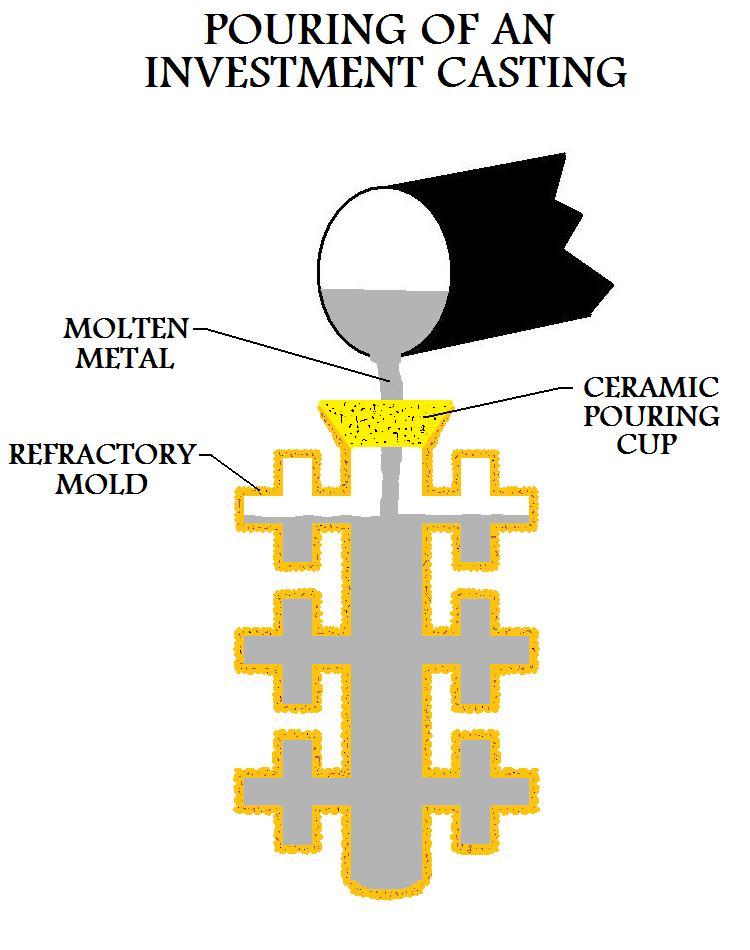

Figure:54

|

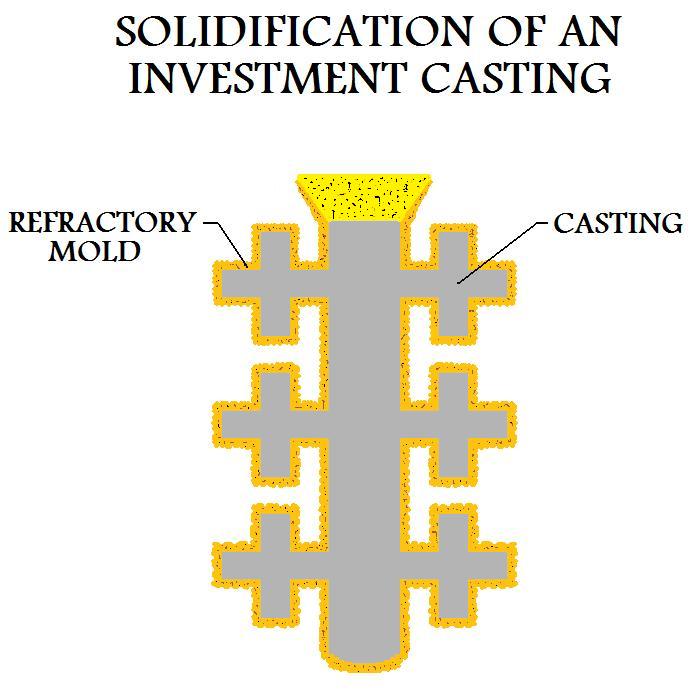

After pouring of the molten metal into the mold, the casting is allowed to set as the solidification process takes place.

Figure:55

|

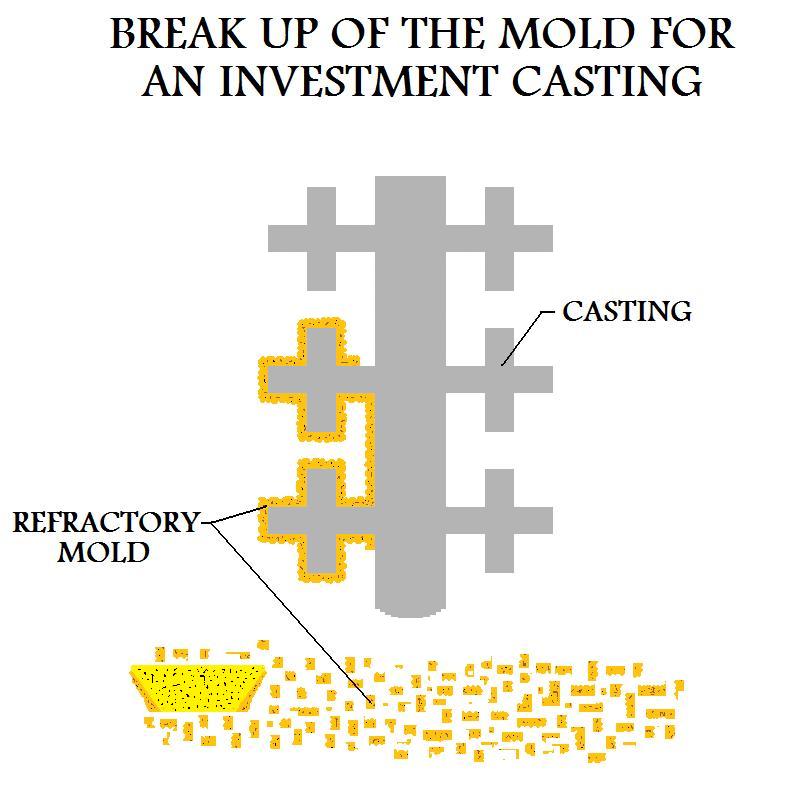

The final step in this manufacturing process involves breaking the ceramic mold from the investment casting and cutting the parts from the tree.

Figure:56

|

Figure:57

|

Properties And Considerations Of Manufacturing By Investment Casting

- Investment casting is a manufacturing process that allows the casting of extremely complex parts, with good surface finish.

- Very thin sections can be produced by this process. Metal castings with sections as narrow as .015in (.4mm) have been manufactured using investment casting.

- Investment casting also allows for high dimensional accuracy. Tolerances as low as .003in (.076mm) have been claimed.

- Practically any metal can be investment cast. Parts manufactured by this process are generally small, but parts weighing up to 75lbs have been found suitable for this technique.

- Parts of the investment process may be automated.

- Investment casting is a complicated process and is relatively expensive.