METAL CASTING

PROCESSES

Metal Casting Principles

Metal Casting

Metal Casting Operation

Effect Of Gases On Metal Casting

Metal Casting Design

Expendable Mold Casting

Sand Casting

Plaster Mold Casting

Ceramic Mold Casting

Shell Mold Casting

Vacuum Casting or V-process

Expanded Polystyrene Casting

Investment Casting

Permanent Mold Casting

Basic Permanent Mold Casting

Slush Casting

Pressure Casting

Vacuum Permanent Mold Casting

Hot Die Casting

Cold Die Casting

True Centrifugal Casting

Semicentrifugal Casting

Centrifuge Casting

Ingot Casting

Continuous Casting

MANUFACTURING

PROCESSES

Metal Forming

Metal Rolling

Metal Forging

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

Die Casting Manufacture

Die casting is a permanent mold manufacturing process that was developed in the early 1900's. Die casting manufacture is characteristic in that it uses large amounts of pressure to force molten metal through the mold. Since so much pressure is used to ensure the flow of metal through the mold, metal castings with great surface detail, dimensional accuracy, and extremely thin walls can be produced. Wall thickness within castings can be manufactured as small as .02in (.5mm). The size of industrial metal castings created using this process vary from extremely small to around 50lbs. Typical parts made in industry by die casting include tools, toys, carburetors, machine components, various housings, and motors.

The Process

The Mold

Like in all permanent mold manufacturing processes, the first step in die casting is the production of the mold. The mold must be accurately created as two halves that can be opened and closed for removal of the metal casting, similar to the basic permanent mold casting process. The mold for die casting is commonly machined from steel and contains all the components of the gating system. Multi-cavity die are employed in manufacturing industry to produce several castings with each cycle. Unit dies which are a combination of smaller dies are also used to manufacture metal castings in industry.

In a die casting production setup, the mold, (or die), is designed so that its mass is far greater than that of the casting. Typically the mold will have 1000 times the mass of the metal casting. So a 2 pound part will require a mold weighing a ton! Due to the extreme pressures and the continuous exposure to thermal gradients from the molten metal, wearing of the die can be a problem. However in a well maintained manufacturing process, a die can last hundreds of thousands of cycles before needing to be replaced.

Die Casting Machines

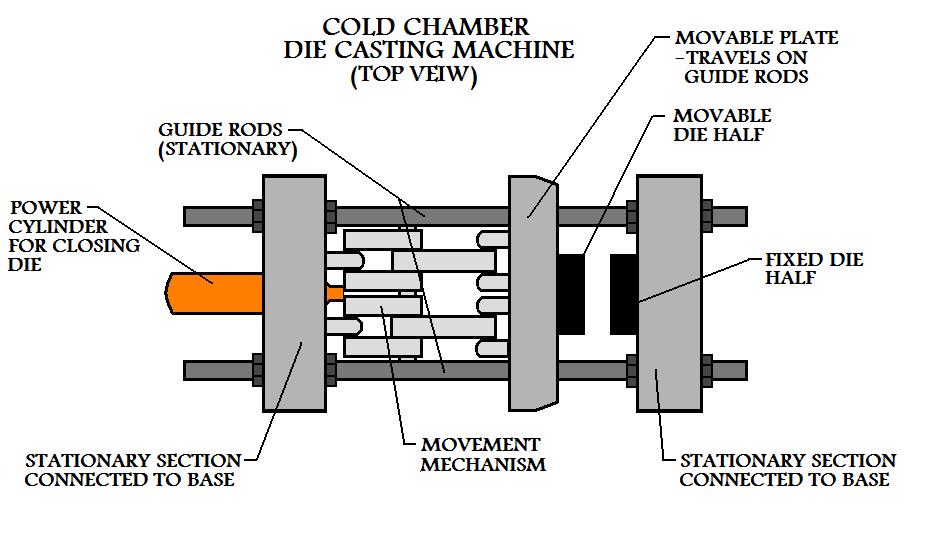

In addition to the opening and closing of the mold to prepare for and remove castings, it is very important that there is enough force that can be applied to hold the two halves of the mold together during the injection of the molten metal. Flow of molten metal under such pressures will create a tremendous force acting to separate the die halves during the process. Die casting machines are large and strong, designed to hold the mold together against such forces.

Figure:81

|

In manufacturing industry, die casting machines are rated on the force with which they can hold the mold closed. Clamping forces for these machines vary from around 25 to 3000 tons.

Injection Of Molten Metal

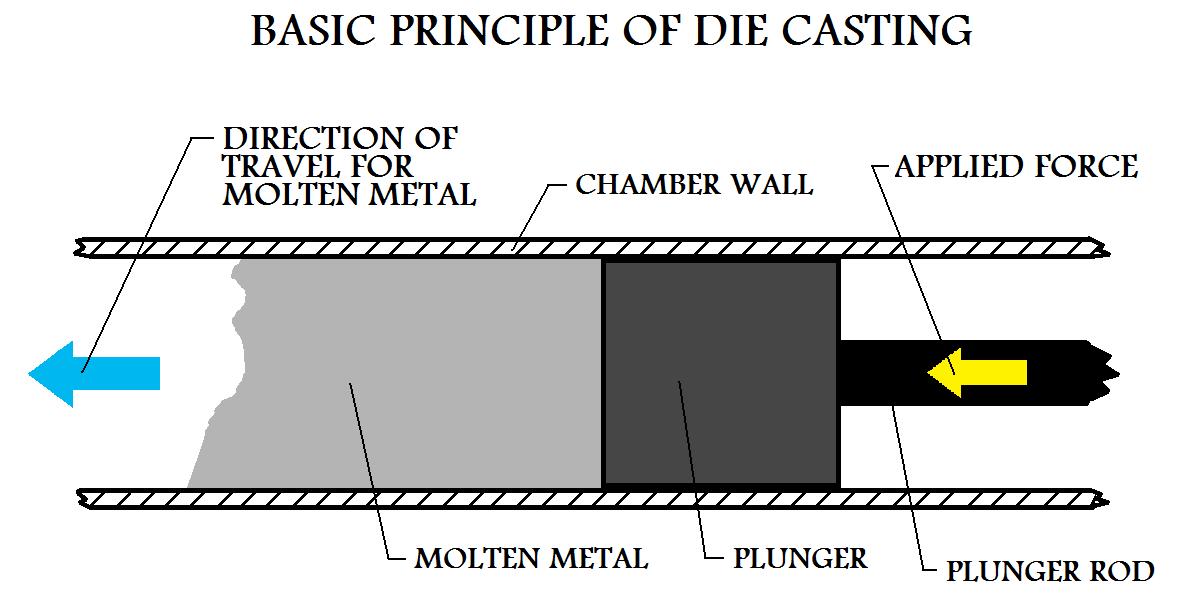

In industrial manufacture the process of die casting falls into two basic categories, hot chamber die casting and cold chamber die casting. Each process will be discussed specifically in more detail later. Although these processes vary from each other, both employ a piston or plunger to force molten metal to travel in the desired direction.

Figure:82

|

The pressure at which the metal is forced to flow into the mold in die casting manufacture is on the order of 1000psi to 50000psi (7MPa to 350MPa). This pressure is accountable for the tremendously intricate surface detail and thin walls that are often observed in metal castings manufactured by this technique.

Once the mold has been filled with molten metal, the pressure is maintained until the casting has hardened. The mold is then opened and the casting is removed. Ejector pins built into the mold assist in the removal of the metal casting. In most manufacturing operations, the internal surfaces of the mold are sprayed with a lubricant before every cycle. The lubricant will assist in cooling down the dies as well as preventing the metal casting from sticking to the mold.

After the casting has been removed and the lubricant applied to the mold surfaces, the die are clamped together again then the cycle will repeat itself. Cycle times will differ depending upon the details of each specific die casting manufacturing technique. In some instances, very high rates of production have been achieved using this metal casting process.

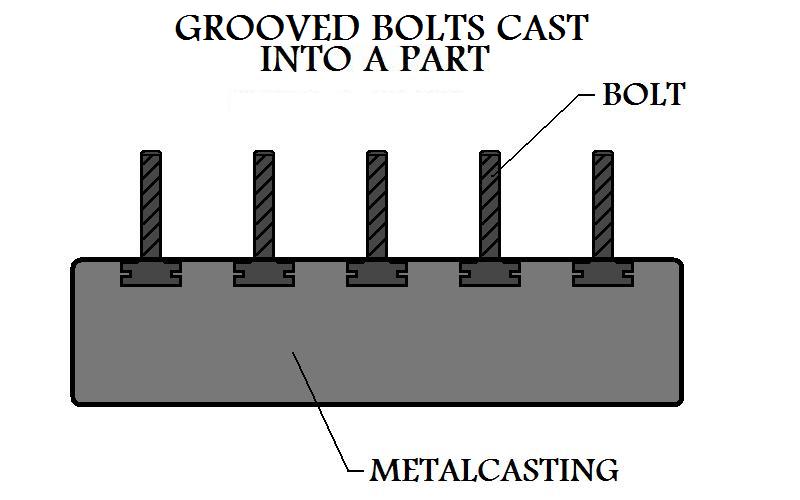

Insert Molding

With the die casting process, shafts, bolts, bushings and other parts can be inserted into the mold and the metalcasting may be formed around these parts. This is called insert molding, once solidified these parts become one with the casting. To help with the integration of the part into the casting, the part may be grooved or knurled providing a stronger contact surface between the part and the molten metal.

Figure:83

|

Properties And Considerations Of Manufacturing By Die Casting

- Metal castings with close tolerances, tremendous surface detail, and thin intricate walls can be

manufactured using this process.

- Due to the rapid cooling at the die walls smaller grain structures are formed, resulting in

manufactured metal castings with superior mechanical properties. This is especially true of the thinner

sections of the casting.

- When manufacturing by this process, it is of concern to keep the mold cool. Die may have special

passages built into them that water is cycled through in order to keep down thermal

extremes.

- High production rates are possible in die casting manufacture.

- Since the mold is not permeable, adequate vents need to be provided for the elimination of

gases during the metal casting process. These vents are usually placed along the parting line

between the die.

- Due to the high pressures, a thin flash of metal is usually squeezed out at the parting

line. This flash has to be trimmed latter from the casting.

- Ejector pins will usually leave small round marks on the metal casting. These can be observed

on the surfaces of manufactured parts.

- The need to open and close the mold limits some of the shapes and geometries

that may be cast using this manufacturing process.

- Equipment cost for die casting are generally high.

- Die casting manufacture can be highly automated, making labor cost low.

- Die casting is similar to most other permanent mold casting processes in that

high set up cost, and high productivity make it suitable for larger batch manufacture and

not small production runs.