METAL CASTING

PROCESSES

Metal Casting Principles

Metal Casting

Metal Casting Operation

Effect Of Gases On Metal Casting

Metal Casting Design

Expendable Mold Casting

Sand Casting

Plaster Mold Casting

Ceramic Mold Casting

Shell Mold Casting

Vacuum Casting or V-process

Expanded Polystyrene Casting

Investment Casting

Permanent Mold Casting

Basic Permanent Mold Casting

Slush Casting

Pressure Casting

Vacuum Permanent Mold Casting

Die Casting

Hot Die Casting

Cold Die Casting

True Centrifugal Casting

Centrifuge Casting

Ingot Casting

Continuous Casting

MANUFACTURING

PROCESSES

Metal Forming

Metal Rolling

Metal Forging

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

Semicentrifugal Casting

Semicentrifugal casting manufacture is a variation of true centrifugal casting. The main difference is that in semicentrifugal casting the mold is filled completely with molten metal, which is supplied to the casting through a central sprue. Castings manufactured by this process will possess rotational symmetry. Much of the details of the manufacturing process of semicentrifugal casting are the same as those of true centrifugal casting. For a better understanding of this process and centrifugal casting manufacture in general see true centrifugal casting. Parts manufactured in industry using this metal casting process include such things as pulleys, and wheels for tracked vehicles.

The Process

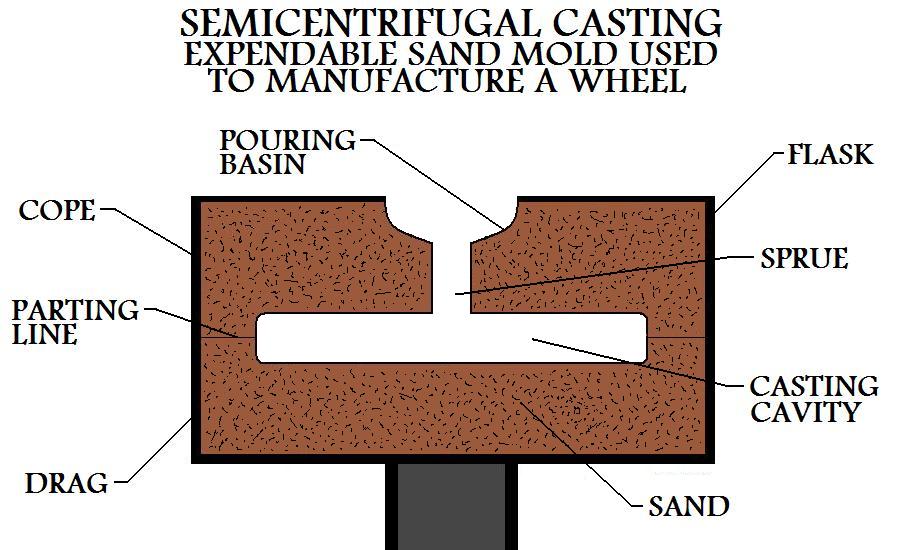

In semi-centrifugal casting manufacture a permanent mold may be employed. However, often industrial manufacturing processes will utilize an expendable sand mold. This enables the casting of parts from high temperature materials.

Figure:96

|

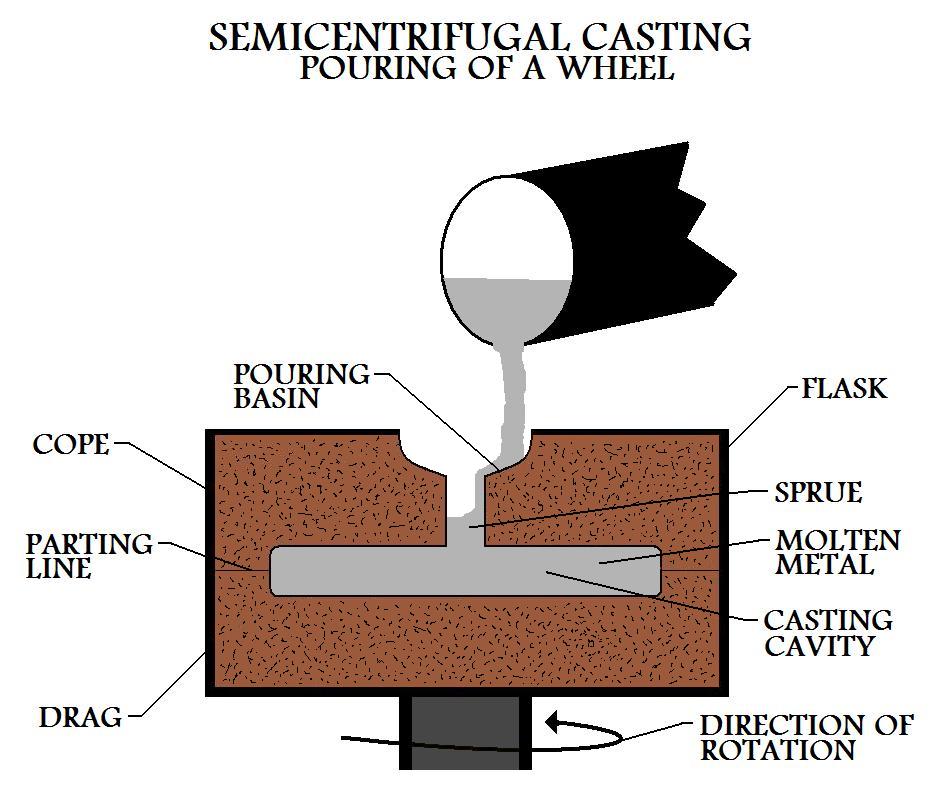

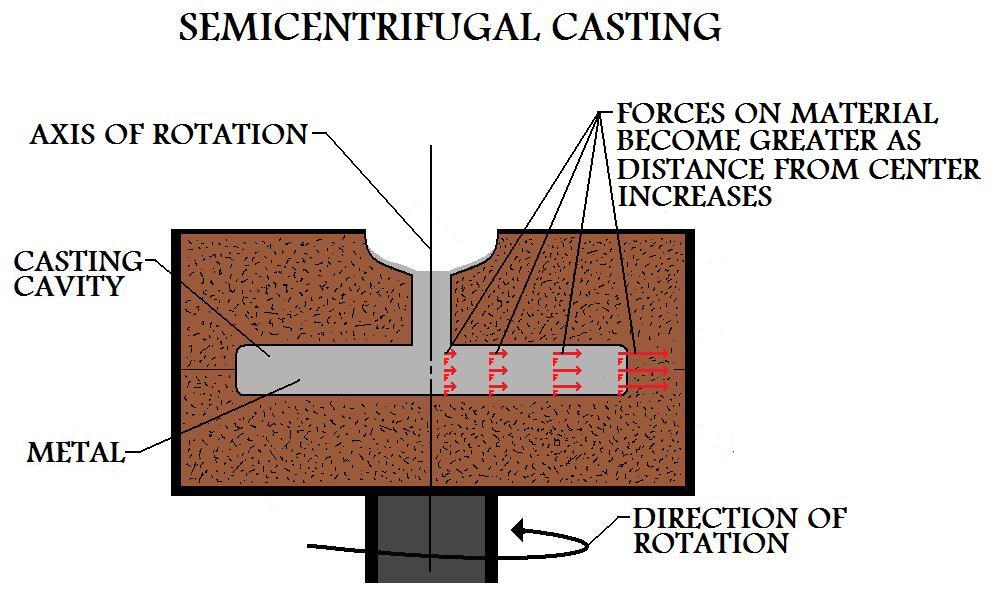

The molten material for the metal casting is poured into a pouring basin and is distributed through a central sprue to the areas of the mold. The forces generated by the rotation of the mold ensure the distribution of molten material to all regions of the casting.

Figure:97

|

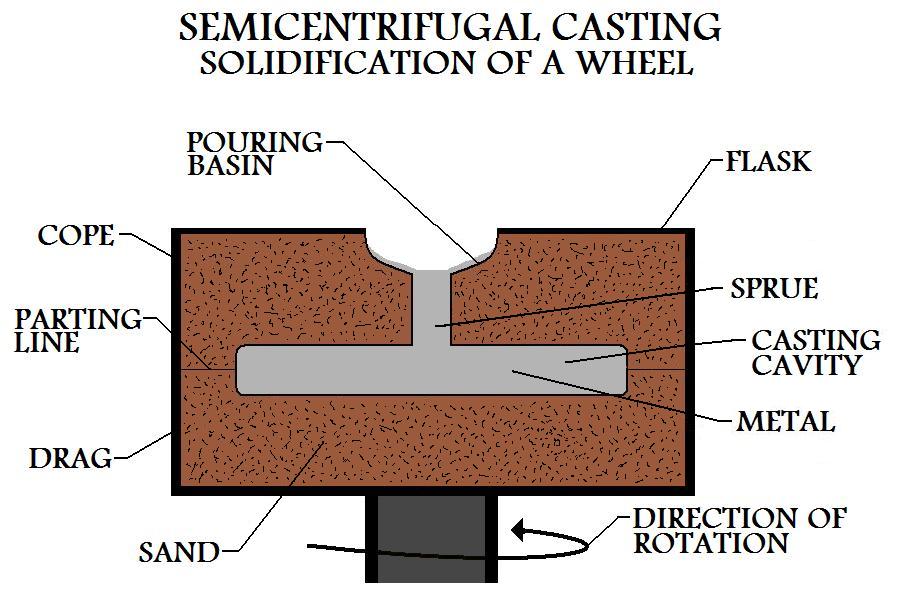

As the metal casting solidifies in a rotating mold, the centripetal forces constantly push material out from the central sprue/riser. This material acts to fill vacancies as they form, thus avoiding shrinkage areas.

Figure:98

|

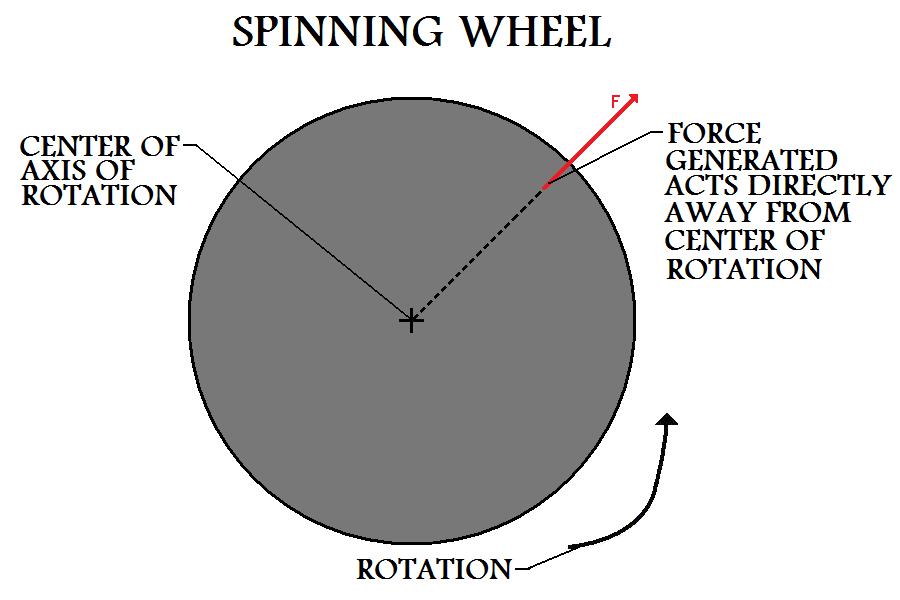

The centripetal forces acting on the casting's material during the manufacturing process of semicentrifugal casting, play a large part in determining the properties of the final cast part. This is also very much the case with cast parts manufactured using the true centrifugal casting process. Forces acting in the true centrifugal process are similar to those that influence the material of a metal casting being manufactured by semicentrifugal casting.

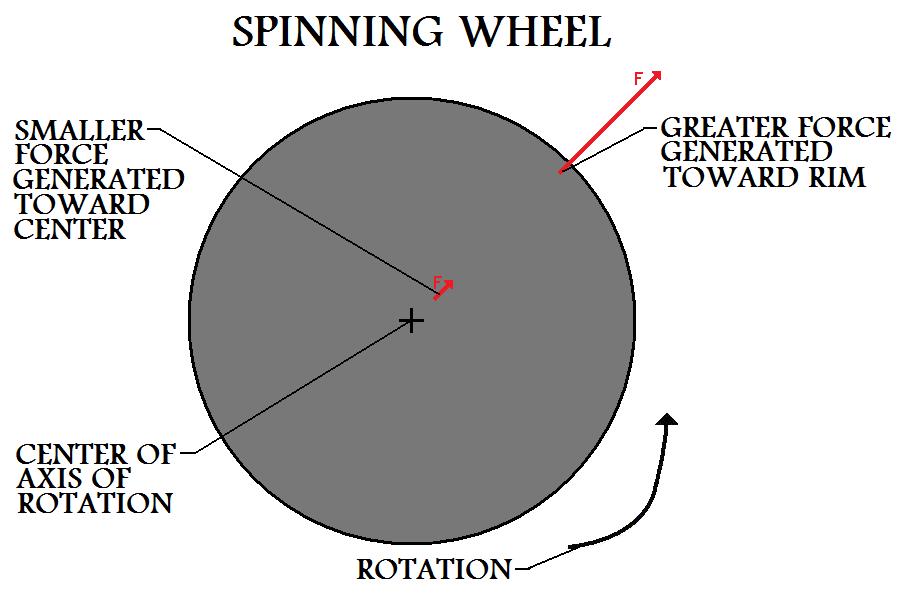

When manufacturing by semi-centrifugal casting, the centripetal acceleration generated on the mass of molten metal by a rotating mold is the force that acts to fill the casting with this molten metal. This is also the force that continues to act on the material as the casting solidifies. The main thing to remember about centripetal forces is that the force will push in a direction that is directly away from the center of the axis of rotation.

Figure:99

|

Also, the farther away from the center of the axis of rotation, the greater the force.

Figure:100

|

It can be seen that during the semicentrifugal manufacturing process, the material in the outer regions of the casting, (further from the center of the axis of rotation), is subject to greater forces than the material in the inner regions.

Figure:101

|

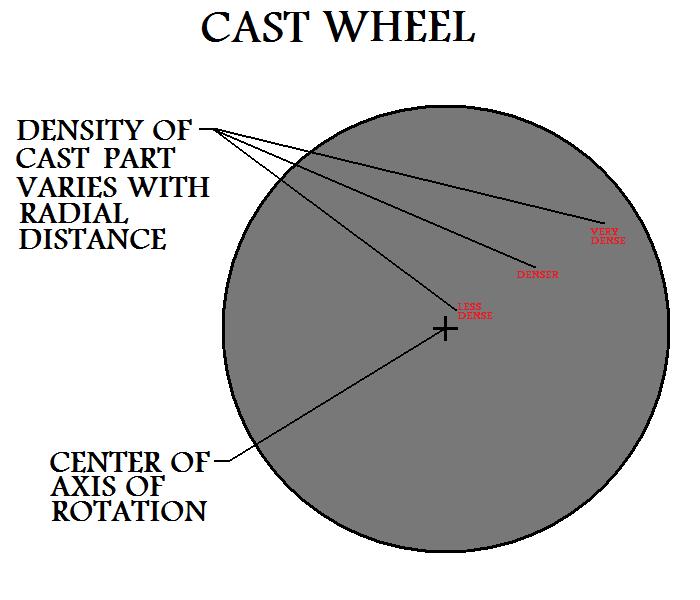

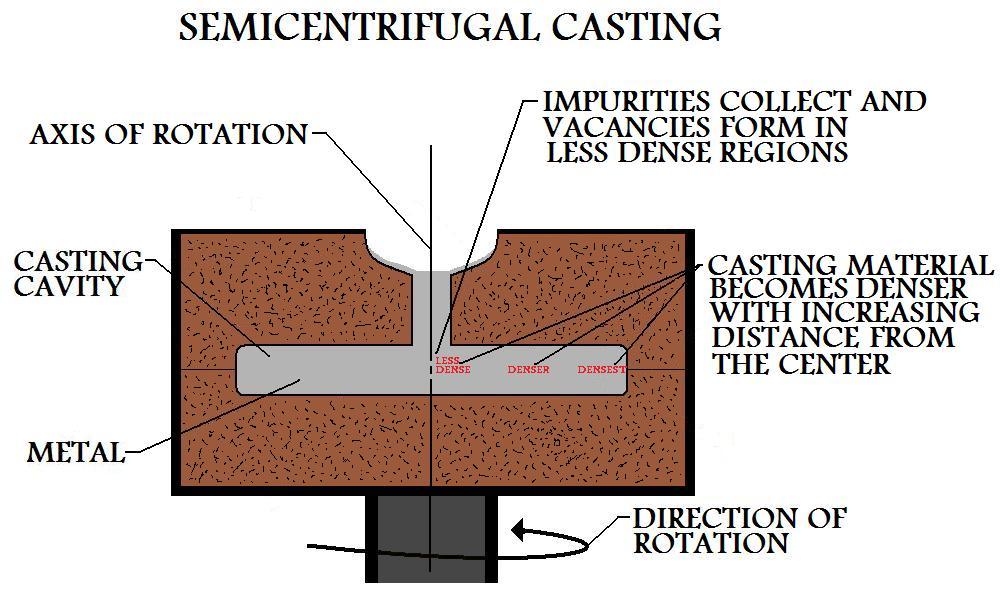

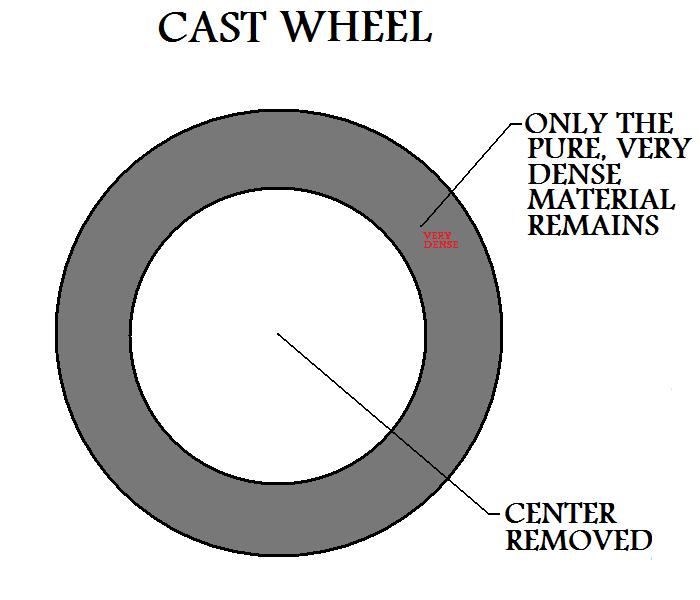

When the metal casting solidifies, the outer region of the cast part forms of dense material. The greater the forces under which the molten metal solidified, the denser the material in that region. So the density of a cast part manufactured by semicentrifugal casting will increase as you travel radially outward from the center.

Figure:102

|

The high forces in the outer section that push the molten material against the mold wall also ensure a great surface finish of cast parts manufactured by semicentrifugal casting. Another feature of this process, attributed to the usage of centripetal forces, is that impurities within the metal, (such as solid inclusions and trapped air), will form towards the inner regions of the casting. This occurs because the metal itself is denser than the impurities, denser material subject to centripetal forces will tend to move towards the rim, forcing less dense material to the inner regions. This particular detail is also a feature in other types of centrifugal casting manufacture.

Figure:103

|

In industrial manufacture of parts by semicentrifugal casting, it is common to machine out the impurity filled center section, leaving only the purer, denser outer region as the final cast part.

Figure:104

|