Slush Casting

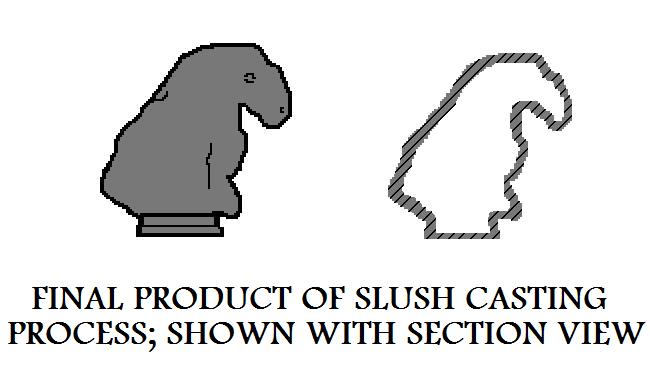

Slush casting is a variation of permanent mold casting that is used to

produce hollow parts. In this method neither the strength of the part nor its internal geometry can

be controlled accurately. This metal casting process is used primarily to manufacture toys and parts that

are ornamental in nature, such as lamp bases and statues.

The Process

When producing a cast part using the slush casting method, a permanent mold is employed and

set up. See basic permanent mold casting .

The mold is clamped together and prepared for pouring.

Figure:64

|

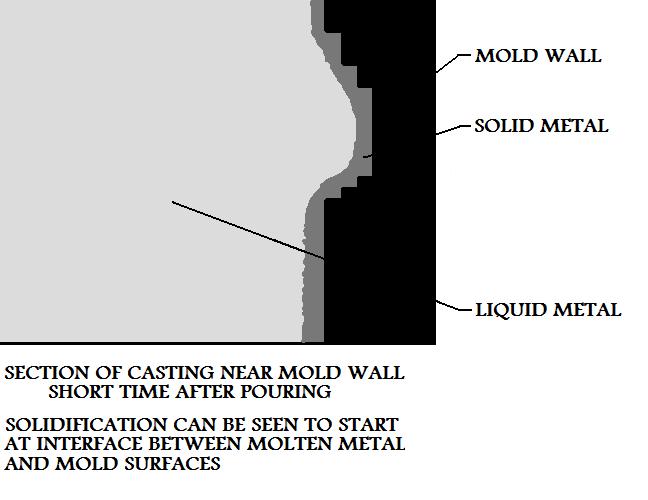

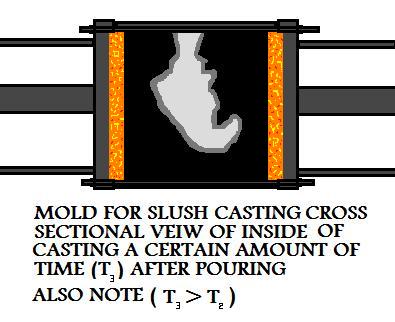

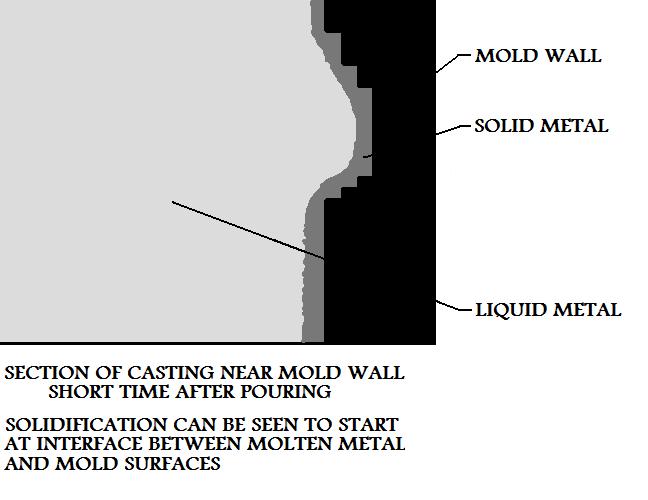

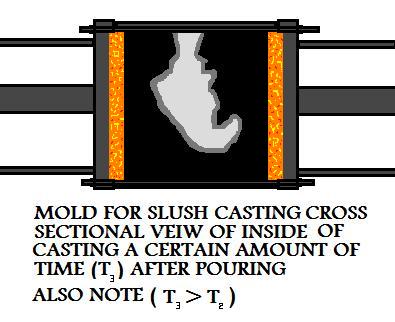

After pouring the mold will set, as solidification begins to take place.

Figure:65

|

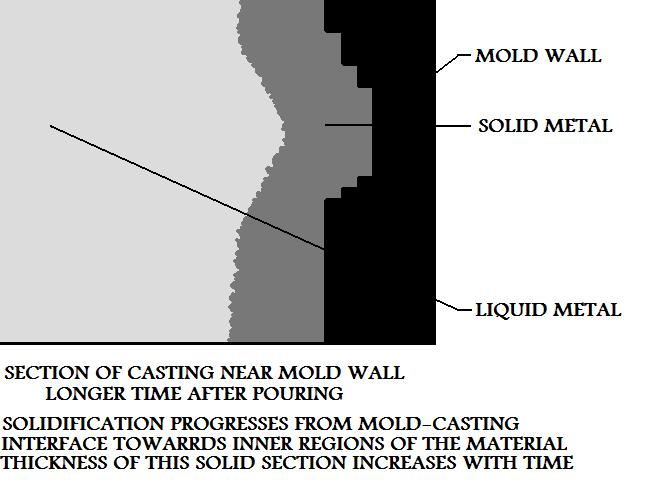

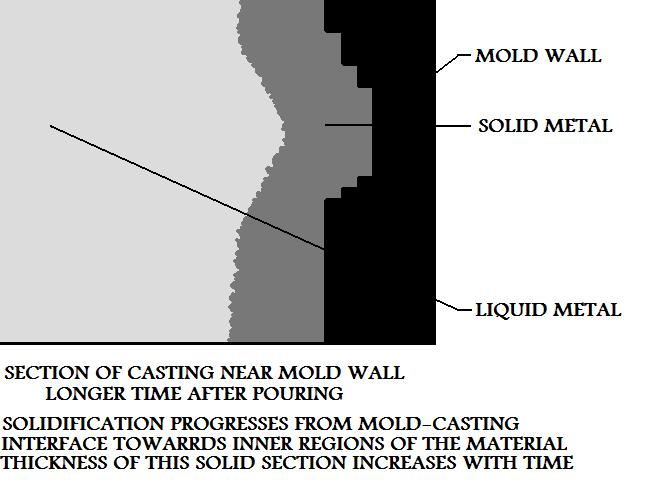

The main principle of this casting process relies on the fact that when a metal casting

hardens in a mold, it will solidify from the mold wall towards the inside of the casting. In

other words a metal skin forms first, (as the external geometry of the part). This skin

thickens as more of the metal casting's material converts to a solid state.

Figure:66

|

Figure:67

|

Figure:68

|

Figure:69

|

Figure:70

|

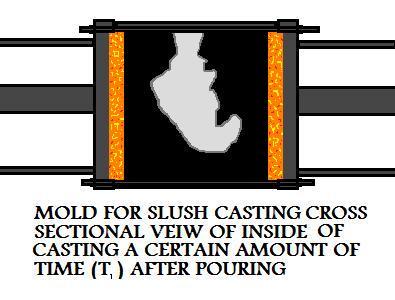

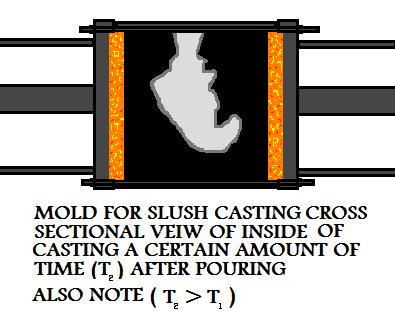

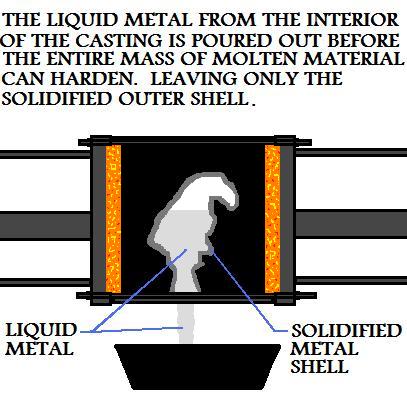

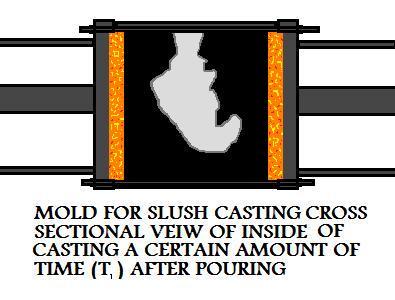

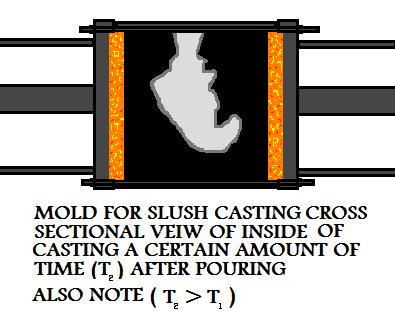

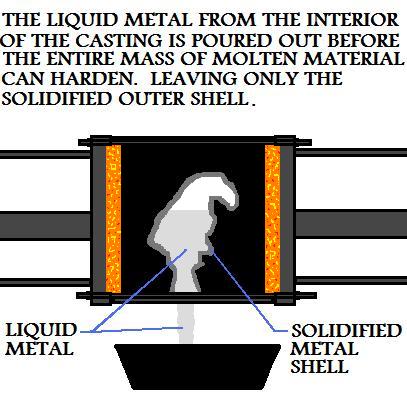

In slush mold casting, during the solidification of the material, when the solid-liquid boundary

has reached a certain point, the mold is turned over and the remaining liquid metal from the casting

is poured out.

Figure:71

|

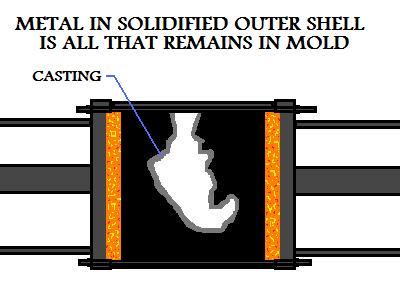

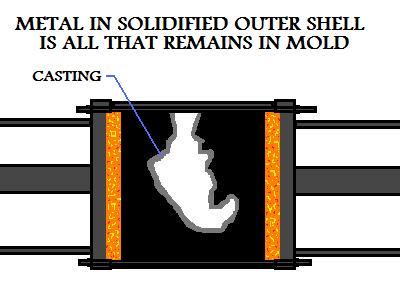

This will leave only the solidified skin with the exterior geometry of the metal cast part and a

hollow interior. The longer the metal casting was allowed to solidify before pouring out the excess

metal, the greater the casting's wall thickness will be.

Figure:72

|

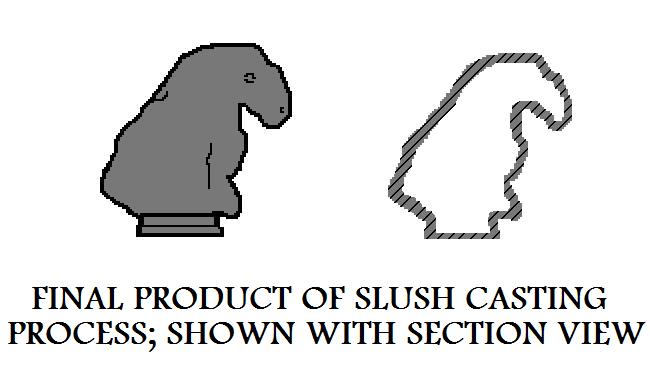

The cast part is then removed from the die and allowed to cool.

Figure:73

|

Properties And Considerations Of Manufacturing

By Slush Casting

- Slush casting is a type of permanent mold casting, therefore many of the basic

principles of a permanent mold process will apply.

- Slush casting is mainly suited to lower melting point materials, zinc, tin, or

aluminum alloys are commonly slush cast in manufacturing industry.

- With this process you need to have a mechanical means of turning over the

mold in order to pour out the molten metal from the cast part.

- When manufacturing by slush casting it is difficult to accurately control the

metal casting's strength and other mechanical properties.

- The casting's internal geometry cannot be effectively controlled with

this process.

- The hollow metal castings manufactured by this process are lighter than solid

parts and save on material.

- Good surface finish and accurate exterior geometry are possible with the

slush casting manufacturing process.

TOP

|