METAL CASTING

PROCESSES

Metal Casting

Principles

Metal Casting

Metal Casting Operation

Effect Of Gases On Metal Casting

Metal Casting Design

Expendable

Mold Casting

Sand Casting

Plaster Mold Casting

Ceramic Mold Casting

Shell Mold Casting

Vacuum Casting or V-process

Expanded Polystyrene Casting

Investment Casting

Permanent

Mold Casting

Slush Casting

Pressure Casting

Vacuum Permanent Mold Casting

Die Casting

Hot Die Casting

Cold Die Casting

True Centrifugal Casting

Semicentrifugal Casting

Centrifuge Casting

Ingot Casting

Continuous Casting

MANUFACTURING

PROCESSES

Metal Forming

Metal Rolling

Metal Forging

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

Basic Permanent Mold Casting

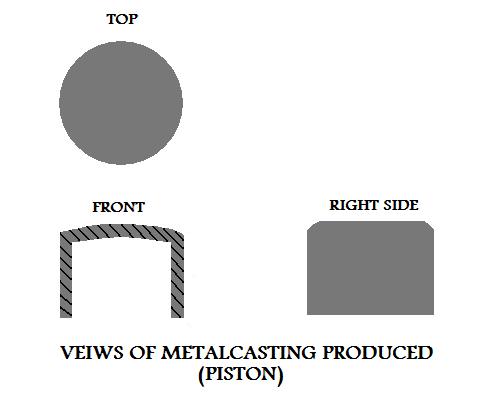

Basic permanent mold casting is a generic term used to describe all permanent mold casting processes. The main similarity of this group being the employment of a permanent mold that can be used repeatedly for multiple metal castings. The mold also called a die, is commonly made of steel or iron, but other metals or ceramics can be used. Parts that may be manufactured in industry using this metal casting process include cylinder blocks, cylinder heads, pistons, connecting rods, parts for aircraft and rockets, gear blanks and kitchenware.

The Process

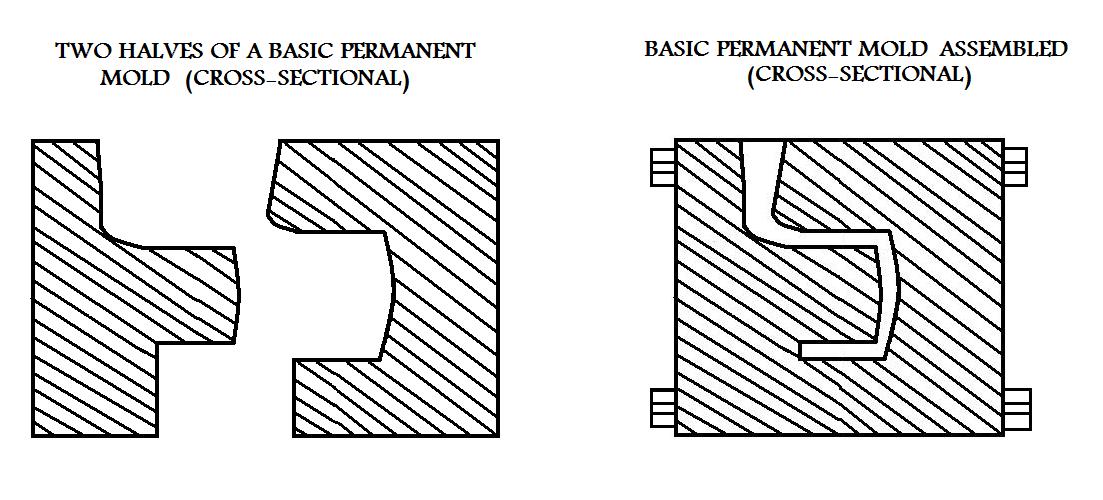

When planning to manufacture using a permanent mold manufacturing process the first step is to create the mold. The sections of the mold are most likely machined from two separate metal blocks. These parts are manufactured precisely. They are created so that they fit together and may be opened and closed easily and accurately. The gating system as well as the part geometry is machined into the casting mold.

A significant amount of resources need to be utilized in the production of the mold, making setup more expensive for permanent mold manufacturing runs. However, once created, a permanent mold may be used tens of thousands of times before its mold life is up. Due to the continuous repetition of high forces and temperatures, all molds will eventually decay to the point where they can no longer effectively manufacture quality metal castings. The number of castings produced by that particular mold before it had to be replaced is termed mold life . Many factors affect mold life such as the molds operating temperature, mold material and casting metal.

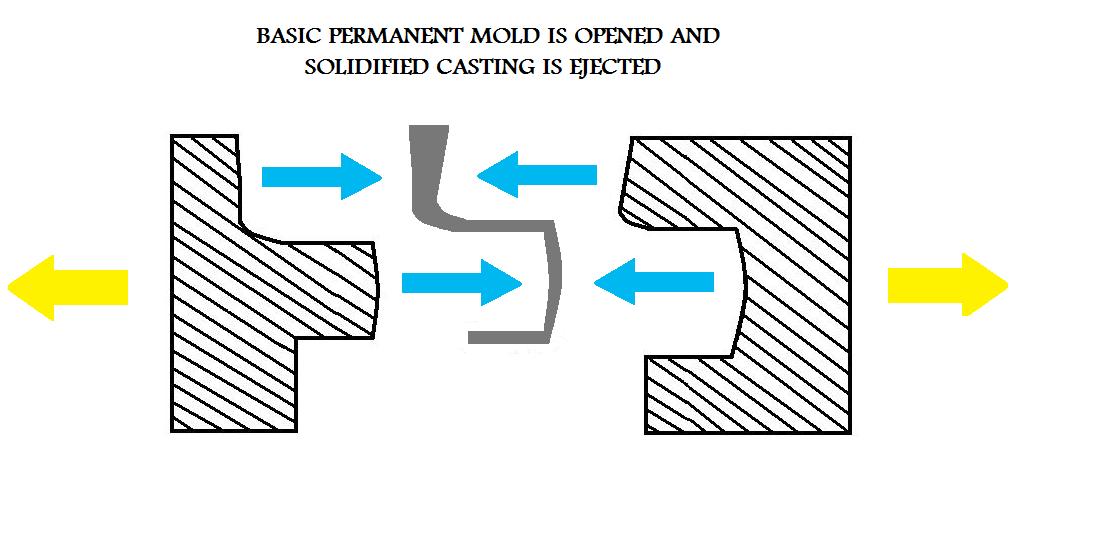

Figure:58  |

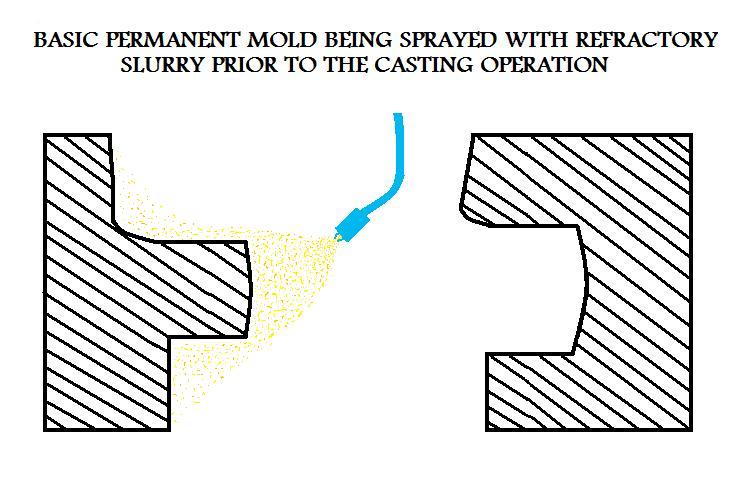

Before pouring the metal casting, the internal surfaces of the permanent mold are sprayed with a slurry consisting of refractory materials suspended in liquid. This coating serves as a thermal gradient, helping to control the heat flow and acting as a lubricant for easier removal of the cast part. In addition, applying the refractory coat as a regular part of the manufacturing process will increase the mold life of the valuable mold.

Figure:59  |

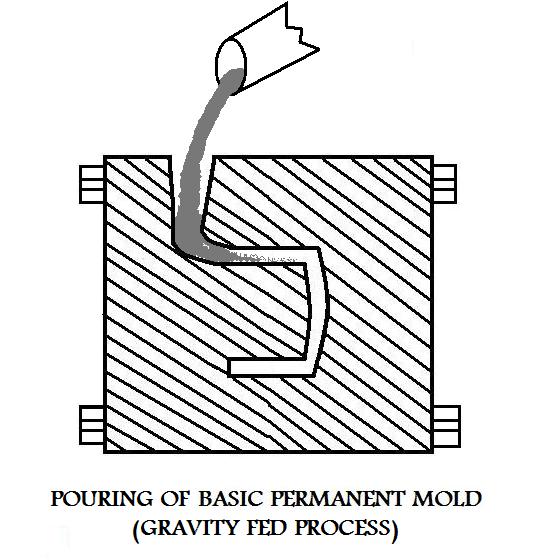

The two parts of the mold must be closed and held together with force, using some sort of mechanical means. Most likely, the mold will be heated prior to the pouring of the metal casting. A possible temperature that a permanent metal casting mold may be heated to before pouring could be around 350F (175C). The heating of the mold will facilitate the smoother flow of the liquid metal through the mold's gating system and casting cavity. Pouring in a heated mold will also reduce the thermal shock encountered by the mold due to the high temperature gradient between the molten metal and the mold. This will act to increase mold life. Once securely closed and heated, the permanent mold is ready for the pouring of the cast part.

Figure:60  |

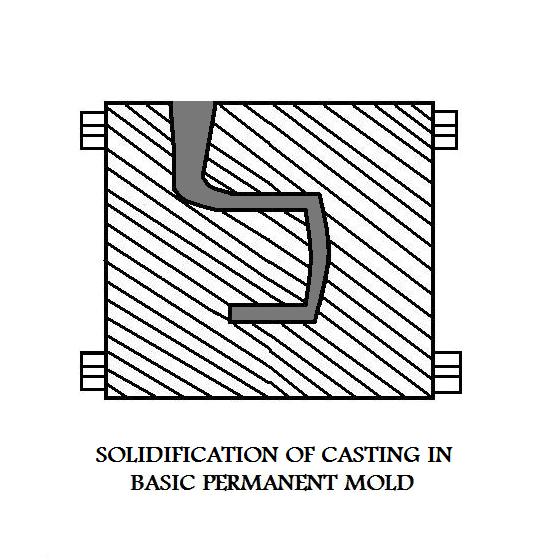

After pouring, the metal casting solidifies within the mold.

Figure:61  |

In manufacturing practice, the metal cast part is usually removed before much cooling occurs, to prevent the solid metal casting from contracting too much in the mold. This is done to prevent cracking the casting, since the permanent mold does not collapse. The removal of the part is accomplished by way of ejector pins built into the mold.

Figure:62  |

Figure:63

|

Cores And Semipermanent Mold Casting

Cores are often employed in a permanent mold metal casting process. These cores are likely made of the same material of the mold and are also permanent. The geometry of the these cores has to allow for the removal of the casting or the cores need to be able to collapse by some mechanical means. Sand cores have a lot less limitations and can be used in conjunction with permanent molds. Sand cores are placed within the permanent mold prior to pouring the metal casting. The sand cores are not permanent, like the mold and must be broken up and replaced with every casting. Sand cores, however, allow for more freedom in the manufacture of internal geometry. In manufacturing industry using a disposable core with a permanent mold is called semipermanent mold casting.

Properties And Considerations Of Manufacturing By Basic Permanent Mold Casting

- Generally this manufacturing process is only suited for materials with lower melting

temperatures, such as zinc, copper, magnesium and aluminum alloys.

- Cast iron parts are also manufactured by this process but the high melting

temperature of cast iron is hard on the mold.

- Steels may be cast in permanent molds made of graphite or some special

refractory material.

- The mold may be cooled by water or heat fins to help with the dissipation of heat

during the metal casting process.

- Due to the need to open and close the mold to remove the work piece,

part geometry is limited.

- If the semi-permanent casting method is used, internal part geometry may be

complex.

- Due to the nature of the mold, the metal casting will solidify rapidly. This will

result in a smaller grain structure, producing a casting with superior mechanical

properties.

- More uniform properties throughout the material of the cast part may also

be observed with permanent mold casting.

- Closer dimensional accuracy as well as excellent surface finish of the part,

is another advantage of permanent mold casting over most expendable

metal casting processes.

- In industrial manufacture permanent mold casting results in a lower

percentage of rejects than many expendable mold processes.

- There is a limitation on the size of cast parts manufactured by this process.

- The initial setup cost are high, making permanent mold casting

unsuitable for small production runs.

- Permanent mold casting can be highly automated.

- This manufacturing process is useful in industry for high volume runs.

When set up, it can be extremely economical with a high rate of

production.