METAL CASTING

PROCESSES

Metal Casting Principles

Metal Casting

Metal Casting Operation

Effect Of Gases On Metal Casting

Metal Casting Design

Expendable Mold Casting

Sand Casting

Plaster Mold Casting

Ceramic Mold Casting

Shell Mold Casting

Vacuum Casting or V-process

Expanded Polystyrene Casting

Investment Casting

Permanent Mold Casting

Basic Permanent Mold Casting

Slush Casting

Pressure Casting

Vacuum Permanent Mold Casting

Die Casting

Hot Die Casting

Cold Die Casting

Semicentrifugal Casting

Centrifuge Casting

Ingot Casting

Continuous Casting

MANUFACTURING

PROCESSES

Metal Forming

Metal Rolling

Metal Forging

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

True Centrifugal Casting

The manufacturing process of centrifugal casting is a metal casting technique, that uses the forces generated by centripetal acceleration to distribute the molten material in the mold. Centrifugal casting has many applications in manufacturing industry today. The process has several very specific advantages. Cast parts manufactured in industry include various pipes and tubes, such as sewage pipes, gas pipes, and water supply lines, also bushings, rings, the liner for engine cylinders, brake drums, and street lamp posts. The molds used in true centrifugal casting manufacture are round, and are typically made of iron, steel, or graphite. Some sort of refractory lining or sand may be used for the inner surface of the mold.

The Process

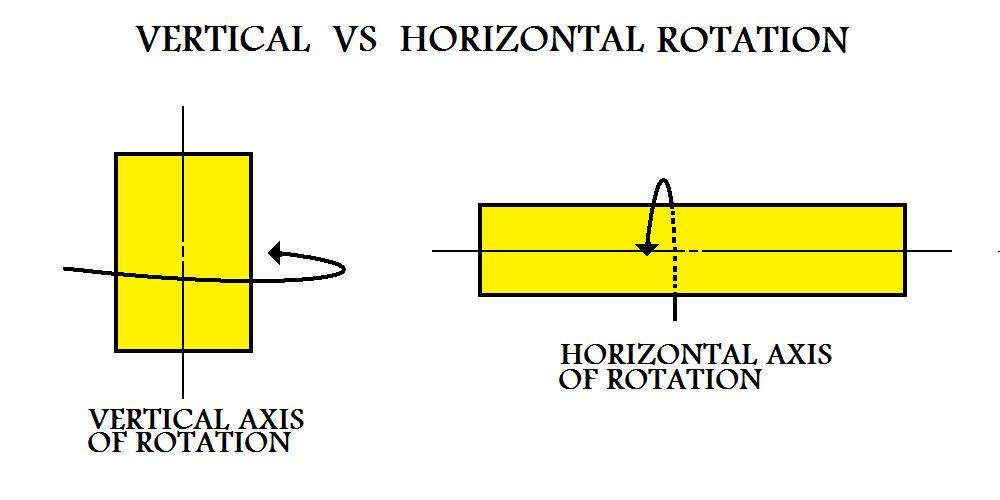

It is necessary when manufacturing a cast part by the true centrifugal metal casting process, using some mechanical means, to rotate the mold. When this process is used for industrial manufacture, this is accomplished by the use of rollers. The mold is rotated about its axis at a predetermined speed. Molds for smaller parts may be rotated about a vertical axis. However, most times in true centrifugal casting manufacture the mold will be rotated about a horizontal axis. The effects of gravity on the material during the metal casting process make it particularly necessary to cast longer parts with forces generated from horizontal rather than vertical rotation.

Figure:91

|

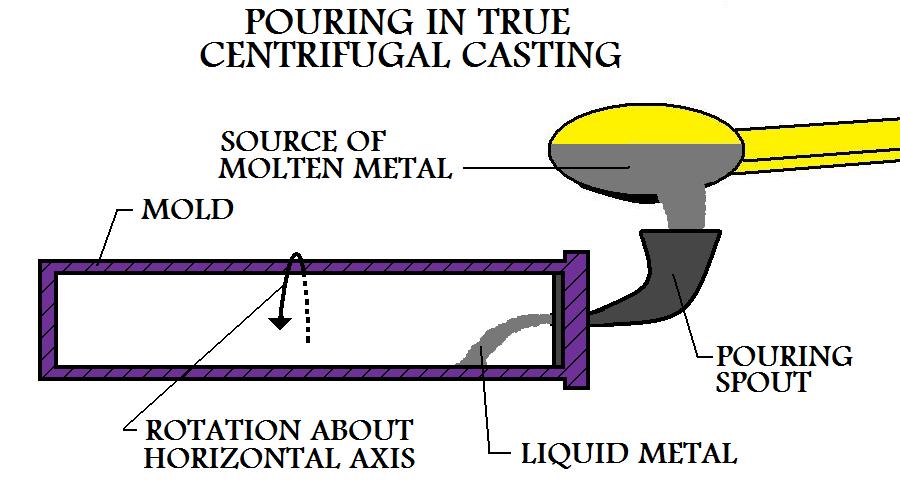

The molten material for the cast part is introduced to the mold from an external source, usually by means of some spout. The liquid metal flows down into the mold. Once inside the cavity, the centripetal forces from the spinning mold force the molten material to the outer wall. Molten material for the casting may be poured into a spinning mold or the rotation of the mold may begin after pouring has occurred.

Figure:92

|

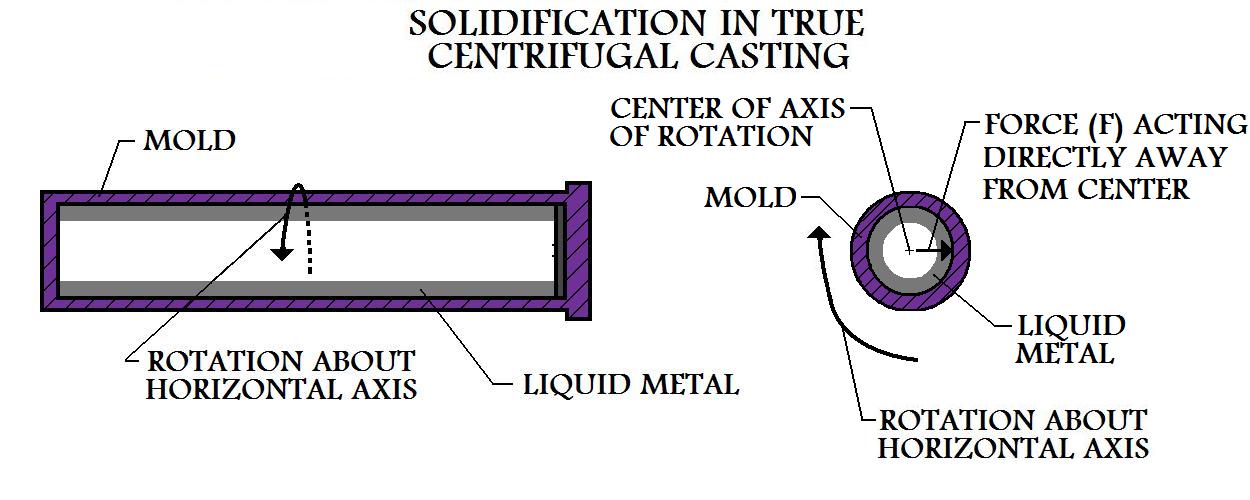

The metal casting will harden as the mold continues to rotate.

Figure:93

|

It can be seen that this casting process is very well suited for the manufacture of hollow cylindrical tubes. The forces used in this technique guarantee good adhesion of the casting material to the surface of the mold. Thickness of the cast part can be determined by the amount of material poured. The outer surface does not need to be round. Polygonal geometries such as squares and other shapes can be cast. However, due to the nature of the process, the inner surface of a part manufactured by true centrifugal casting must always be round.

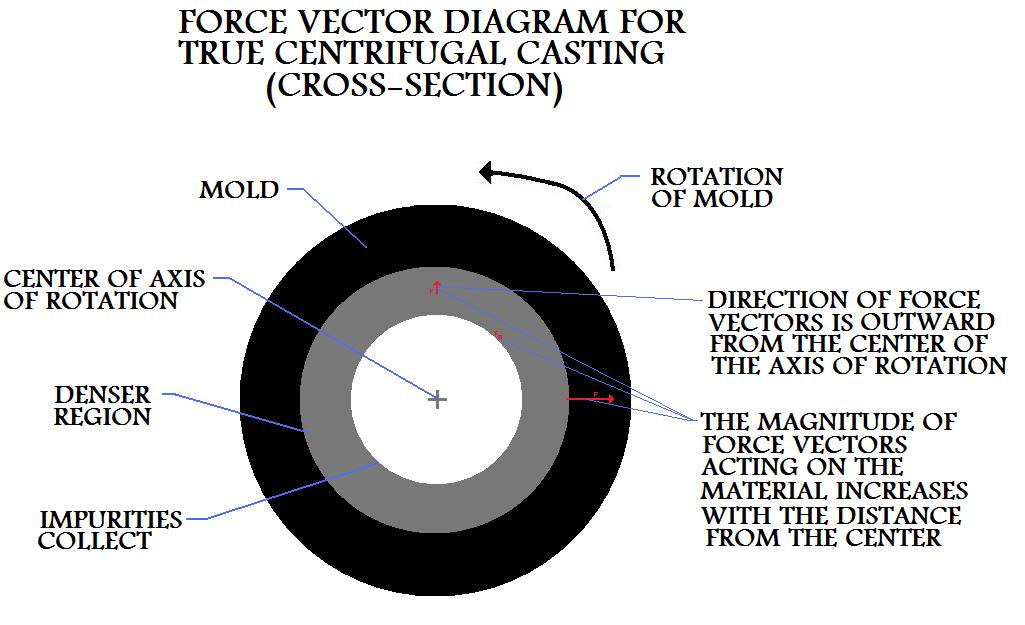

During the pouring and solidification phase of true centrifugal casting, the forces at work play a large roll in the properties of castings manufactured by this process. It can be seen that forces will be greater in the regions further away from the center of the axis of rotation. The greater forces towards the rim will cause the regions of the metal casting nearer the outer surface to have a higher density than the sections located nearer the inner surface.

Figure:95

|

Most impurities within the material have a lower density than the metal itself, this causes them to collect in the inner regions of the metal casting, closer to the center of the axis of rotation. These impurities can be removed during the casting operation or they can be machined off later.

Properties And Considerations Of Manufacturing By True Centrifugal Casting

- True centrifugal casting is a great manufacturing process for producing hollow

cylindrical parts.

- The metal casting's wall thickness is controlled by the amount of material added

during the pouring phase.

- Rotational rate of the mold during the manufacture of the casting must be calculated

carefully based on the mold dimensions and the metal being cast.

- If the rotational rate of the mold is too slow, the molten material for the casting will

not stay adhered to the surface of the cavity. From the top half of the rotation it will

rain metal within the casting cavity as the mold spins.

- This manufacturing operation produces metal cast parts without the need for sprues,

risers, or other gating system elements, making this a very efficient industrial metal casting

process, in terms of material usage.

- Since large forces press the molten material for the cast part against the mold

wall during the manufacturing operation, good surface finish and detail are

characteristic of true centrifugal casting.

- Quality castings with good dimensional accuracy can be produced with this

process.

- Material of high density and with few impurities is produced in the outer

regions of cylindrical parts manufactured by true centrifugal casting.

- Impurities, such as metal inclusions and trapped air, collect in the lower density

inner regions of cylindrical parts cast by this process.

- These inner regions can be machined out of the cast part leaving only the dense,

more pure material.

- Shrinkage is not a problem when manufacturing by true centrifugal casting, since

material from the inner sections will constantly be forced to instantly fill any vacancies

that may occur in outer sections during solidification.

- This method can produce very large metal castings. Cylindrical pipes 10 feet in diameter

and 50 feet long have been manufactured using this technique.

- With the employment of a sand lining in the mold, it is possible to manufacture

castings from high melting point materials such as iron and steels.

- This is a large batch production operation.

- True centrifugal casting is a manufacturing process that is capable of very high

rates of productivity.